Welding thin to thick metal can often be a challenging task, even for experienced welders. It requires a solid grasp of techniques, proper equipment settings, and a keen eye for detail to ensure a strong, clean weld that holds up over time. Whether you’re working on automotive repairs, metal fabrication, or structural projects, understanding how to approach welding metals of different thicknesses is crucial. In this article, we’ll dive deep into tried-and-tested welding approaches and best practices to help you master this technique.

If you want to learn about welding thin metal to thick metal, you’ve come to the right place. We’ll cover everything from preparation, types of welders suited for the job, to specific techniques that minimize warping and burn-through. Additionally, key safety considerations and tips will be woven throughout, ensuring that you not only produce strong welds but do so safely.

Why Welding Thin to Thick Metal is Challenging

When welding thin metal to thick metal, the most common issues welders face are warping, burn-through, and weak welds. But what makes this so difficult? The main reason is the significant difference in heat absorption between thin and thick metals.

Thick metal acts like a heat sink; it absorbs and dissipates the heat much more readily than thin metal. This means when you apply heat to weld the joint, the thin metal can quickly reach a temperature that causes it to burn or melt through before the thick metal is sufficiently heated to form a strong bond.

Here’s a quick breakdown of the challenges:

- Burn-through: Thin metal can easily melt away if too much heat is applied.

- Warping and distortion: Thin metal is more susceptible to warping due to uneven heating.

- Uneven penetration: The thick metal may not properly fuse with the thin metal if the heat isn’t well controlled.

- Inconsistent weld beads: It’s harder to lay consistent weld beads across different thicknesses.

Addressing these challenges means balancing heat input, adjusting machine settings, and employing techniques that protect the thin metal while ensuring adequate fusion with the thick metal.

Understanding Metal Thickness and Why It Matters

Before jumping directly into the welding process, it’s important to understand how metal thickness affects the procedure. Metal thickness is typically measured in gauge or millimeters, and the general rule is: the thicker the metal, the more heat required to produce a proper weld.

For example, thin sheet metals such as 18-gauge (around 1.2mm) require much less heat compared to thicker plates of 1/4 inch (6.35mm) or more. Welding metals that differ drastically—say, 18-gauge sheet metal to a 1/2 inch thick plate—can be quite tricky without the right approach.

Thickness also impacts:

- Welding current: Higher thicknesses demand higher current.

- Welding speed: Thin metals require faster travel speeds to avoid burning through.

- Preheat requirements: Thick metals might need preheating to ensure proper fusion.

- Joint design and fit-up: Adjusting joint design can compensate for varied thicknesses.

Choosing the Right Welding Process for Thin to Thick Metal

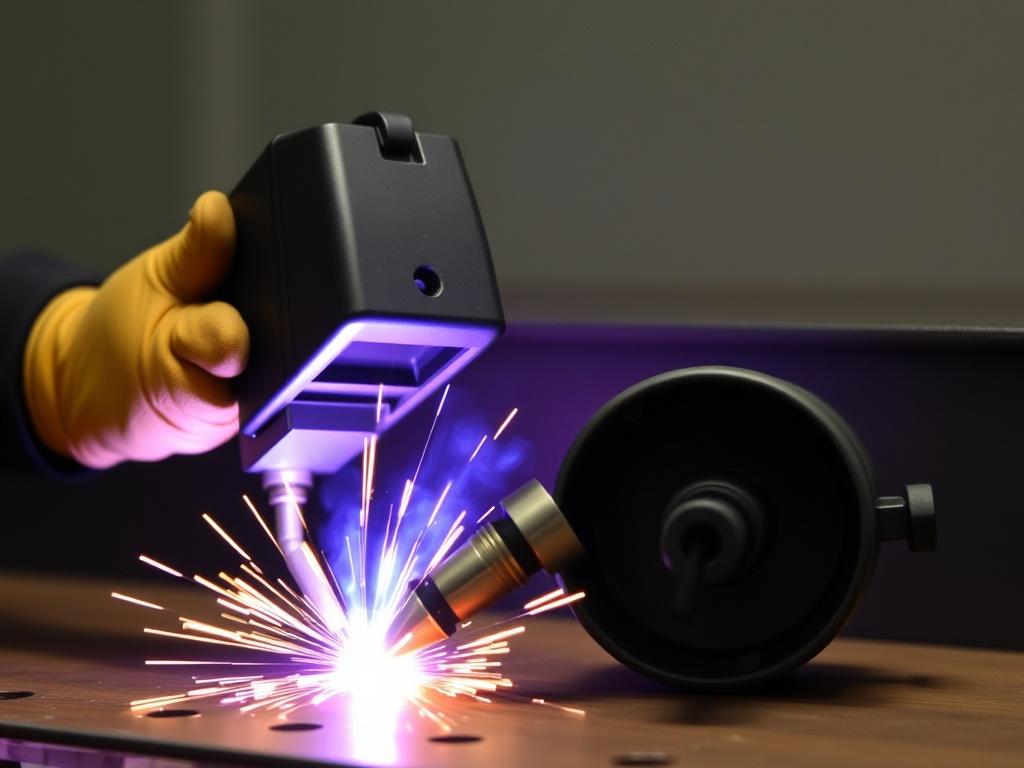

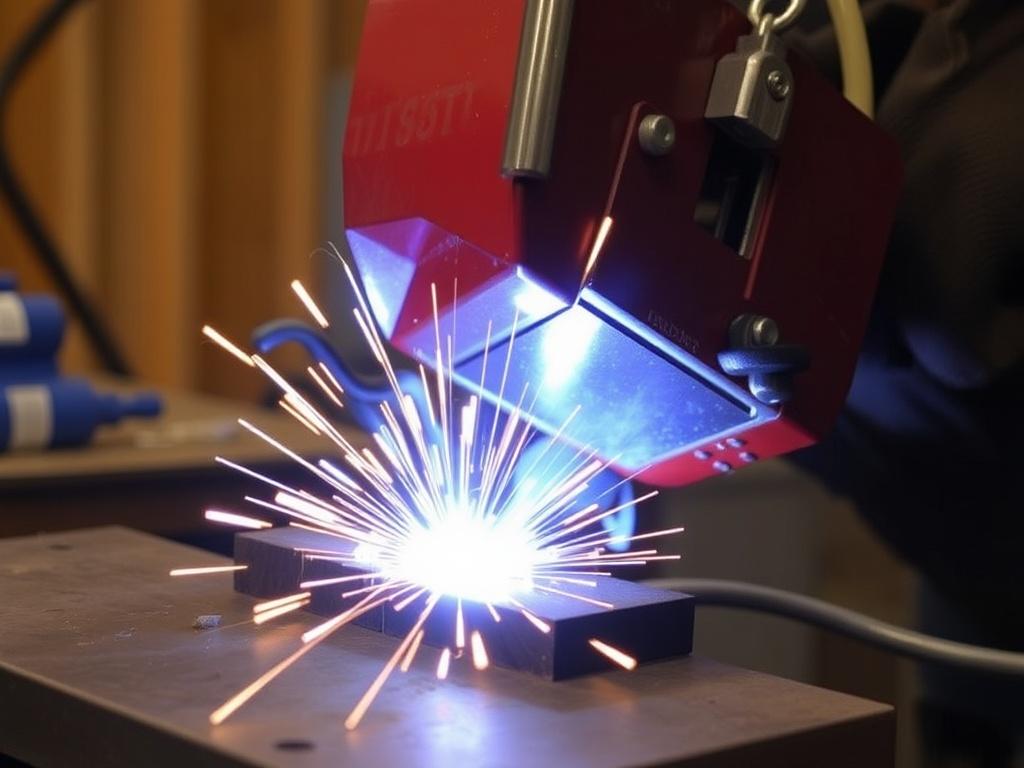

Several welding processes are suitable for welding thin to thick metals, but some work better than others depending on the metals involved, thickness range, and the desired finish. Let’s explore the primary welding methods and their applicability to this scenario.

MIG Welding (Gas Metal Arc Welding – GMAW)

MIG welding is widely used for welding thin to thick metals due to its versatility, speed, and relative ease of use. With the right setup, MIG allows good control over heat input and can produce clean welds without excessive distortion.

To weld thin to thick metal with MIG, consider the following:

- Use pulse MIG settings: Pulsed MIG reduces heat input, protecting thin metal from burn-through.

- Choose the right wire diameter: A thinner wire (0.023” or 0.030”) is effective for thin metals.

- Adjust gas flow and type: Argon/CO2 mixes offer good arc stability.

- Work with short-circuit transfer mode: This reduces heat input on thin sections.

TIG Welding (Gas Tungsten Arc Welding – GTAW)

TIG welding provides unmatched control over heat and weld quality. It’s particularly useful when precision is needed on thin metals and joining to thicker metals.

Key TIG welding tips:

- Use a lower amperage and thinner filler rods: Allows for delicate control.

- Utilize foot pedal control: Enables precise heat management in real-time.

- Maintain a consistent travel speed: Prevents burn-through and uneven weld beads.

While TIG welding is excellent for thin to thick metal welding, it requires more skill and generally takes longer than MIG welding.

Stick Welding (Shielded Metal Arc Welding – SMAW)

Stick welding is typically less ideal for thin metals due to higher heat input and difficulty controlling weld penetration. However, with the right electrode and technique, it can work for specific thick-to-thin welds, especially in outdoor or field repairs.

For stick welding thin to thick metals:

- Use low amperage settings: To avoid burn-through.

- Choose thin electrodes with fast-freeze characteristics: Like E6010 for root passes or E7018 for fill and cap passes.

Other Methods: Laser Welding and Resistance Welding

For industrial applications, laser welding or resistance spot welding might be the best option due to precision and speed with minimal heat distortion. Though these aren’t typically accessible to most DIY or small shops, they’re worth knowing about.

Preparation Tips Before Welding Thin to Thick Metal

Proper preparation is essential for successful welding of dissimilar thickness metals. Neglecting prep work often results in poor weld quality and increased risk of defects.

Cleaning the Metal

Always clean both pieces thoroughly to remove rust, paint, oil, dirt, or other contaminants. Clean surfaces ensure strong welds and reduce the risk of porosity or inclusions within the weld bead.

Joint Design

The way you prepare the joint can make a huge difference. Common joint types include butt joints, lap joints, and edge joints.

For welding thin metal to thick metal, a lap joint often works best because it provides more surface area for weld penetration. Alternatively, a beveled edge on the thicker piece with a square edge on the thin piece can facilitate easier penetration.

Fit-Up and Clamping

Ensure the parts fit snugly together. Gaps can cause poor penetration, while overly tight joints might cause warping. Use clamps or magnets to hold the metal in place during welding to maintain proper alignment and control heat-induced distortion.

Preheating Thick Metal

When working with thick metal, preheating helps reduce thermal shock and allow better fusion. This is especially true when welding metals prone to cracking such as certain steels.

| Metal Thickness | Recommended Preheat Temperature | Notes |

|---|---|---|

| Up to 1/4 inch (6.35 mm) | Generally no preheat needed | Use controlled heat input during welding |

| 1/4 inch to 1/2 inch (6.35 mm to 12.7 mm) | 150-250°F (65-120°C) | Helps reduce cracking and improves weld penetration |

| Over 1/2 inch (12.7 mm) | 250-400°F (120-205°C) or higher | Depends on alloy type; consult welding procedure specifications |

Techniques to Successfully Weld Thin to Thick Metal

Let’s get into specific techniques to help you weld thin to thick metals effectively. Although techniques vary slightly depending on the welding method used, the principles are largely the same.

1. Use Step or Stitch Welding

Instead of welding a continuous bead along the joint, use a step or stitch welding method. Weld short sections, then skip a small gap and weld another section. This reduces heat concentration, which prevents warping and burn-through on the thin metal.

After completing the initial stitch welds, go back and fill in the skipped areas referring to the heat control techniques discussed earlier.

2. Control Heat Input

Heat control is vital. Balance the amperage and travel speed so that you deliver enough heat to penetrate the thick metal but not so much that it melts through the thin metal.

Things to consider:

- Lower amperage: Use the lowest amperage capable of penetrating the thick piece.

- Faster travel speed: Prevents overheating the thin metal.

- Pulsed welding: Reduces continuous heat input.

3. Use Backing Bars or Heat Sinks

Backing bars made of copper or steel can absorb excess heat from the thin metal, protecting it from burn-through. Placing a backing bar behind the weld area is an excellent way to increase heat dissipation and improve weld quality.

4. Step Down Welding Technique

Start welding on the thicker metal side and progress towards the thin metal, reducing heat input as you move closer to the thin section. This approach helps achieve proper fusion without over-stressing the thin metal.

5. Proper Electrode or Filler Wire Selection

Match your filler material to the base metals for strength and compatibility. When welding steel, ER70S-6 or similar wires are common. For aluminum or stainless steel, appropriate filler rods are needed.

Common Mistakes to Avoid When Welding Thin to Thick Metals

Even with good knowledge, some mistakes can sabotage your weld. Watch out for these pitfalls:

- Applying too much heat: Leads to burn-through or warping of thin metal.

- Ignoring joint fit-up: Gaps cause poor penetration and weak welds.

- Failure to clean metals: Contaminants cause porosity and weld defects.

- Using wrong welding process or settings: Can result in welds that lack strength or are cosmetically poor.

- Skipping preheating on thick metals prone to cracking: Leads to weld defects.

Step-By-Step Guide: MIG Welding Thin to Thick Metal

Let’s walk through a simple MIG welding procedure tailored to thin-to-thick metal joints. The method outlined here is widely applicable for mild steel alloys.

- Prepare and clean the metal surfaces: Remove rust, paint, and contaminants using a wire brush or grinder.

- Select your wire: Use 0.030” MIG wire with an Argon 75% / CO2 25% gas mix.

- Set machine parameters: Use low amperage settings appropriate to thin metal (roughly 65-90 amps depending on thickness).

- Clamp the metals and set up your joint: Prefer lap joint or beveled edge design.

- Start with tack welds: Place short tack welds along the joint to hold parts securely.

- Perform step welds: Weld small sections (1-2 inches) evenly spaced, moving back and forth.

- Fill in the skipped areas: After initial stitches cool down, fill in the gaps carefully, adjusting travel speed as needed.

- Clean and inspect your weld: Use a wire brush, check for porosity, cracks, or weak spots.

- Apply finishing touches: Grind or polish weld bead if necessary to meet aesthetic or structural standards.

Safety Considerations During Welding

Welding always involves risks like burns, electric shock, toxic fumes, and eye damage. When working with varying metal thicknesses, additional caution is warranted due to the tendency for hot metal to crack or warp unpredictably.

Basic safety best practices include:

- Wear protective gear: Welding helmet with proper lens shade, gloves, flame-resistant clothing, and safety boots.

- Ensure proper ventilation: Weld in well-ventilated areas or use smoke extractors.

- Check your equipment: Regularly inspect your welding tools and cables for damage.

- Keep a clean workspace: Remove flammable materials that could ignite from welding sparks.

- Use fire-resistant clamps and magnets: To secure parts and avoid accidental movement.

Frequently Asked Questions About Welding Thin to Thick Metal

Can I weld aluminum thin metal to thick steel?

Welding aluminum to steel directly is generally not recommended because the two metals have vastly different melting points and physical properties. Special techniques like explosion bonding or friction welding are often required. For most fabricators, mechanical fastening is preferred when joining these dissimilar metals.

Is preheating necessary for thin metals?

No, preheating is usually unnecessary for thin metals and can actually cause more distortion by prolonging heat exposure. Preheat is typically reserved for thick metals or crack-prone alloys.

What wire feed speed should I use when welding thin to thick metal?

Wire feed speed depends on the metal thickness and wire size; generally, a lower wire feed speed is preferred for thinner metals to reduce heat input. For example, with 0.030” wire on thin metals, start slow and gradually adjust.

How do I prevent warping when welding thin to thick metal?

Use stitch or step welding techniques, apply heat evenly, clamp parts tightly, and weld from thick to thin metal areas. Proper cooling times between welds also help minimize distortion.

Summary Table: Techniques for Welding Thin to Thick Metal

| Technique | Purpose | Recommended Application |

|---|---|---|

| Step or Stitch Welding | Reduces heat input and warping | Thin to thick metal joints with risk of distortion |

| Backer Bars/Heat Sinks | Protects thin metal from burn-through | Critical when welding very thin sheet metal |

| Controlled Heat Input | Prevents melting of thin metal and uneven penetration | All welding methods, essential for thin metal welding |

| Proper Joint Design | Optimizes fit-up and weld strength | Thick and thin metal combinations |

| Use Pulsed MIG or TIG | Allows greater heat control | MIG and TIG welding of thin to thick metals |

Final Thoughts

Welding thin to thick metal is a nuanced skill that blends art and science. With the right preparation, methods, and mindset, you can overcome the challenges that come with this task. Whether you’re a hobbyist or a professional welder, mastering these techniques will improve your weld quality, reduce rework, and expand your capabilities.

Remember, practice is key—start on scrap metal samples to dial in your settings, and gradually move to your final project. Don’t be discouraged by initial difficulties; with patience and attention to technique, welding thin to thick metals becomes a manageable and even rewarding process. Keep this guide handy, and you’ll have a solid foundation of knowledge to refer back to whenever the job calls for it.

Happy welding!