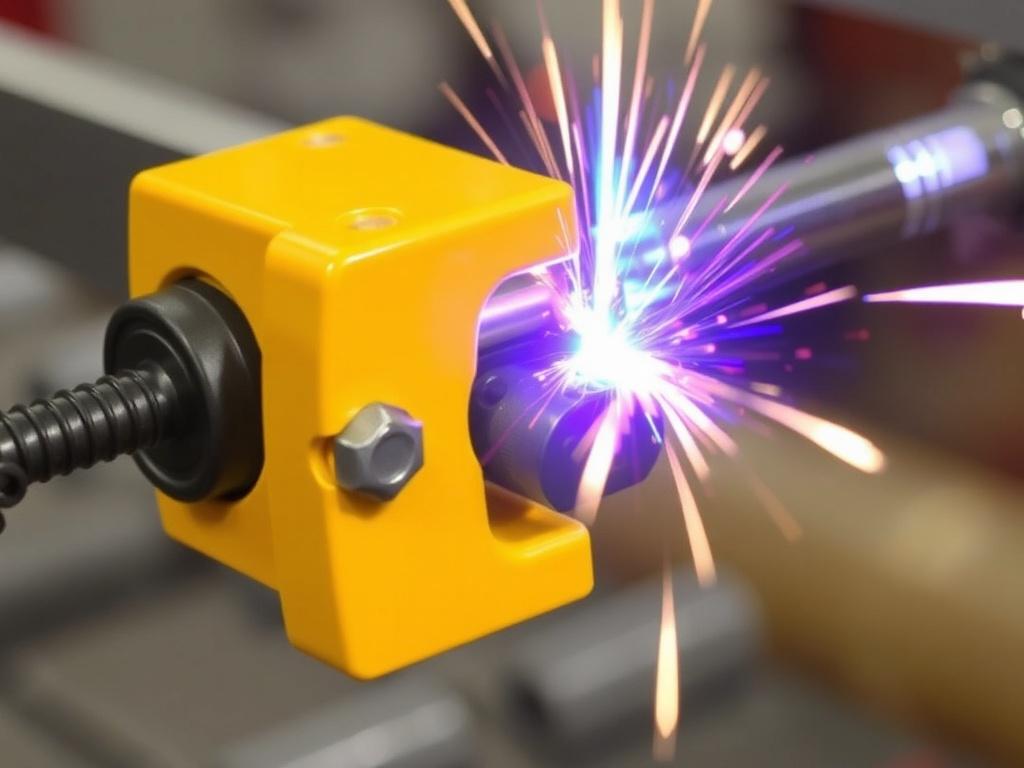

Welding is both an art and a science, requiring precision, patience, and the right set of tools to ensure a flawless job. Whether you are a beginner or a seasoned welder, alignment plays a crucial role in determining the quality of your weld joints. However, achieving perfect alignment can be quite challenging without the appropriate aids. This is where magnets and clamps step in as indispensable tools that enhance welding alignment, reduce errors, and boost productivity.

In this extensive article, we will explore everything you need to know about using magnets and clamps for better welding alignment. We’ll cover the fundamentals, dive into different types of magnets and clamps, discuss practical applications, and provide expert tips to perfect your welding projects. By the end, you’ll feel confident about incorporating these tools into your workflow and achieving professional-level welds.

Understanding Welding Alignment: Why Does It Matter?

Before diving into the tools, it’s important to understand what welding alignment is and why it’s so critical. Welding alignment refers to the proper positioning of metal pieces before and during the welding process. Good alignment ensures that the weld joint is strong, durable, and adheres correctly to the design specifications.

Think of welding alignment as laying the foundation for a building—if the foundation is misaligned, the entire structure can suffer. In poor alignment scenarios, you might face issues like weak joints, warping, misfit, or the need for costly rework. Precise alignment saves time, reduces material wastage, and guarantees safer, higher-quality welds.

The key challenges during alignment involve holding pieces firmly in place, maintaining correct angles, and being able to adjust the parts easily. Without secure and adjustable support, pieces can shift during welding due to heat distortion or manual handling.

Common Welding Alignment Problems

- Shifting Parts: Movement when the weld pool is hot can cause uneven seams.

- Poor Fit-Up: Gaps or overlaps due to misaligned edges.

- Angle Errors: Incorrect bevel or lap angles leading to weak joints.

- Heat Distortion: Warping of metal pieces because of uneven heat distribution.

- Time Delays: Rework and adjustments costing valuable time.

These common problems underscore the importance of using alignment aids in welding. Magnets and clamps are game changers in this regard.

Magnets for Welding Alignment: Types and Benefits

Magnets are among the most versatile and effective tools for ensuring welding alignment. They provide a hands-free approach to holding metal pieces together in the desired position, freeing the welder’s hands for other tasks. Let’s explore how magnets work in welding and what types are available.

How Welding Magnets Work

Welding magnets are typically made from strong ferromagnetic materials designed to securely attach to steel and other ferrous metals. The magnetic force holds the metal pieces in place at specific angles, allowing for precise positioning during welding. These magnets come in various shapes and sizes, commonly featuring preset angle configurations such as 45°, 90°, or 135° to help align parts at exact angles.

The main benefit is the ability to hold heavy metal pieces without the need for clamps or complex setups, reducing setup time significantly.

Types of Welding Magnets

| Type | Description | Typical Uses | Advantages |

|---|---|---|---|

| Triangle Magnets | Triangular shape with fixed angles (45°, 90°, 135°) | Positioning metal pieces for T-joints, corner welds | Easy to position and very strong holding power |

| Flat Magnets | Flat rectangular pieces with magnetic surface | Holding flat sheets, aligning edges | Compact and adaptable to various shapes |

| Adjustable Magnetic Clamps | Magnets combined with adjustable arms or pivots | Custom angles, complex assemblies | Flexible positioning, high precision |

| Magnetic Welding Squares | Specialized square-shaped magnets for 90° alignment | Right angle joints and frames | Consistent 90° hold, simplifies assembly |

Benefits of Using Magnets for Welding Alignment

Magnets bring numerous benefits to the welding process, making them highly popular among professionals and hobbyists alike.

- Hands-Free Operation: Magnets securely hold pieces without manual gripping, allowing welders to focus on the weld.

- Speedy Setup: Quick attachment and repositioning save precious time during prep.

- Improved Precision: Fixed angle magnets ensure consistent alignment for common joints.

- Versatility: Work with different shapes and sizes of steel parts.

- Reusable and Durable: Most magnets are sturdy and can be used repeatedly.

Despite these benefits, magnets are not solely sufficient for all welding jobs, which is why they are often paired with clamps.

Clamps for Welding Alignment: Essential Tools for Stability

While magnets work excellently for many applications, clamps complement them by providing mechanical holding power that is adjustable and strong. Clamps are physical devices that secure metal pieces in place through pressure, preventing movement during the welding process.

Types of Welding Clamps

There is a wide variety of clamps available to meet specific welding needs. Some common types include:

- C-Clamps: Classic design with threaded screw for tightening, ideal for general purposes.

- Locking C-Clamps (Vise-Grip): Can be locked firmly in place and released easily; great for holding tough joints.

- F-Clamps: Adjustable sliding arm, suited for larger or irregular shapes.

- Corner Clamps: Specifically designed to hold pieces at 90° angles, very useful for frame assembly.

- Spring Clamps: Quick to apply and release, helpful for light-duty or temporary holds.

- Toggle Clamps: Provide quick-release clamping with consistent pressure, common in jigs and fixtures.

How Clamps Enhance Welding Alignment

Clamps provide steady mechanical pressure that stabilizes parts during the entire welding cycle, which is especially important where magnets alone might not hold due to shape or material type (e.g., non-ferrous metals). Clamps can also be combined with magnets for complex assemblies where both holding power and angle precision are needed.

Moreover, clamps allow for fine adjustments in fit-up and alignment that can be locked in place securely—a vital feature when working on critical projects that require exact precision.

Advantages of Using Clamps in Welding

- Firm Hold: Provides constant force even on uneven surfaces.

- Flexible Application: Works with all types of metals, including non-magnetic materials.

- Adjustable Pressure: Allows for careful control of tightness to avoid deforming parts.

- Durable and Reliable: Clamps are built to withstand harsh welding environments.

- Complements Magnets: Used together, they create the perfect system for complex weld setups.

Combining Magnets and Clamps for Optimal Welding Alignment

Using magnets and clamps in tandem is a winning strategy that leverages the strengths of both tools. Magnets quickly position pieces at predetermined angles, while clamps lock joints firmly, preventing any slip or distortion during welding.

Practical Techniques for Using Magnets and Clamps Together

Let’s outline a step-by-step approach on how these tools can be combined effectively:

- Prepare Workpieces: Clean all metal surfaces to remove rust, paint, or oils that might interfere with welding or magnet holding power.

- Apply Magnetic Holders: Attach magnetic holders to rough align parts in the correct angular position.

- Fine-Tune Position: Manually adjust parts as needed for exact fit-up while the magnets hold them lightly.

- Secure With Clamps: Position clamps to grip the workpieces firmly at key points, locking the alignment in place.

- Double-Check Angles: Use welding squares or angle finders to confirm precise alignment.

- Proceed with Welding: With magnets and clamps in place, begin welding, confident that the joint will remain stable.

- Remove Tools After Cooling: Once welding is complete and cooled, remove clamps and magnets carefully.

Case Study: Fabricating a Steel Frame with Magnets and Clamps

Imagine you are building a steel rectangular frame that must be perfectly square. Here’s how magnets and clamps assist:

- You use 90° magnetic welding squares to position each corner quickly and reliably.

- Once all four corners are magnetically aligned, you place corner clamps on each joint to lock the corners firmly against movement or warping.

- By combining these two tools, the frame remains stable, enabling smooth tack welding without adjusting or re-clamping every time.

- Post tack, permanent welds can be made swiftly and accurately, resulting in a frame that is square and strong.

Choosing the Right Magnets and Clamps for Your Welding Needs

Not all magnets or clamps are created equal, and different welding jobs require different tools. When selecting these, consider factors such as metal type, thickness, shape of materials, and the type of weld joint.

Factors to Consider When Choosing Magnetic Holders

| Factor | Description | Impact |

|---|---|---|

| Magnetic Strength | Measured in pounds or kilograms of holding force | Stronger magnets hold heavy parts firm but can be hard to position |

| Angular Options | Fixed or adjustable angles offered by the magnet | Helps fit common weld joints like 45°, 90°, or custom angles |

| Material Compatibility | Some magnets work only with ferrous metals | Non-ferrous metals require clamps or special magnetic setups |

| Size and Shape | From small compact magnets to large holding plates | Larger workpieces need bigger magnets or multiple units |

Factors to Consider When Choosing Welding Clamps

- Clamping Force: Ensure clamps can exert sufficient pressure without damaging the workpiece.

- Jaw Size and Opening: Adapt to the thickness and shape of your workpieces.

- Adjustability: For complex joints, adjustable clamps provide versatility.

- Material Durability: High-quality steel clamps hold up better in welding environments.

- Ease of Use: Quick-release or locking features improve efficiency on repetitive tasks.

Expert Tips for Efficient Welding Alignment Using Magnets and Clamps

To maximize the benefits of magnets and clamps in your welding processes, consider these expert recommendations:

1. Keep Your Tools Clean

Dirt, rust, and welding slag on magnets or clamps will reduce their holding effectiveness. Regularly clean and inspect your tools.

2. Use Multiple Tools When Necessary

For larger assemblies, distribute magnets and clamps evenly to avoid sagging or misalignment.

3. Test Fit-Up Before Welding

Do a dry run of assembly using magnets and clamps to confirm alignment before applying any welds.

4. Mind Heat Effects

Magnets can lose strength when exposed to high heat. Try to keep welds away from direct contact or use clamps in high-temperature zones.

5. Combine With Measuring Tools

Always use squares, protractors, or angle finders to double-check alignment beyond just holding tools.

6. Work in Well-Lit Areas

Good lighting helps spot misalignment early and improves precision.

Maintenance and Safety Considerations

Proper maintenance of your magnets and clamps ensures longevity and consistent performance.

Maintenance Tips

- Lubricate clamp screws and hinges occasionally to prevent rust.

- Store magnets away from electronics and devices sensitive to magnetic fields.

- Inspect clamps for wear and replace any damaged parts promptly.

- Keep welding surfaces on clamps and magnets smooth and free of burrs.

Safety Measures

Magnets and clamps can pose safety risks if mishandled. Magnets attract metal objects forcefully, which can cause injuries. Clamps, if over-tightened, can deform or break workpieces or themselves.

- Use gloves to protect your hands when handling strong magnets.

- Be cautious when separating magnets from metal surfaces to avoid pinched fingers.

- Do not rely solely on magnets for safety-critical or load-bearing welds.

- Wear appropriate personal protective equipment (PPE) during welding, including eye protection to guard against sparks.

Summary: Mastering Welding Alignment with Magnets and Clamps

Magnets and clamps are fundamental tools that provide unparalleled advantages in welding alignment. While magnets speed up the setup by offering strong magnetic hold and preset angles, clamps excel at providing firm and adjustable mechanical grip. Together, they deliver the precision and stability that every welder needs to create strong, neat, and reliable weld joints.

By understanding the types of magnets and clamps, how to use them correctly, and what to consider when choosing your tools, you can significantly enhance your welding quality and efficiency. Whether you’re fabricating small parts or constructing large assemblies, incorporating these tools into your workflow will streamline the process and reduce errors.

As with all welding equipment, regular maintenance and safety precautions are essential to keep your magnets and clamps in good working order and to ensure a safe working environment.

So the next time you step up to your welding project, consider how you might use magnets and clamps to get the job done better, faster, and with confidence. Remember: perfect alignment leads to perfect welds — and perfect welds make all the difference.

Additional Resources

- Welding Magazine – Industry news and tips for welders

- Lincoln Electric Welding Guides – Expert tutorials and guides

- Miller Welding & Fabrication – Product catalogs and tutorials

Happy welding, and may your joints always be perfectly aligned!