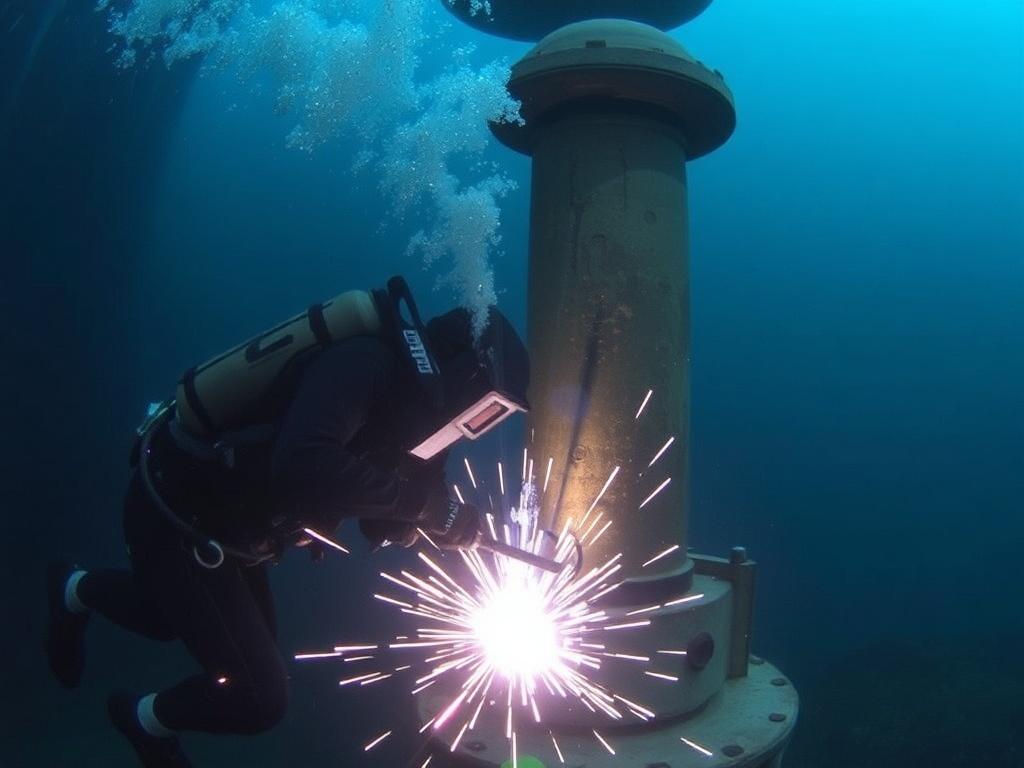

Imagine being submerged deep beneath the ocean’s surface, surrounded by crushing water pressure, cold temperatures, and limited visibility, while performing one of the most precise and hazardous tasks known to man — welding metal structures. This is the reality faced by underwater welders, professionals who combine mastery of welding techniques with the challenging environment of the underwater world. Underwater welding is unquestionably one of the most dangerous jobs on the planet, demanding both exceptional skill and bravery.

In this extensive article, we’ll explore the fascinating world of underwater welding, delving into the nature of the job, the dangers involved, how welders train and prepare for it, and why despite the risks, this profession continues to attract adventurers and craftsmen alike. Whether you are considering diving into this field or just curious about what it entails, there’s a lot to uncover.

What Is Underwater Welding?

Underwater welding, also known as hyperbaric welding, is a unique process where metal components are joined together below the surface of water, typically the ocean, lakes, or rivers. This technique is essential for the maintenance and repair of marine infrastructure, including oil rigs, pipelines, ship hulls, and bridges. By welding underwater, businesses can avoid the massive costs and complications of removing structures to the surface for repairs.

Underwater welding can be performed in two primary ways: wet welding and dry welding.

Wet Welding

Wet welding occurs with the diver directly in the water, welding the metal while submerged. This method is faster and generally cheaper but exposes the welder directly to water, increasing the risk of electric shocks and other hazards.

Dry Welding

Dry welding, also called habitat welding, involves creating a dry chamber around the work area filled with gas, allowing the welder to work in a dry environment. This approach reduces some risks but requires complicated and expensive setup.

The Life of an Underwater Welder: A Day in the Deep

An average workday for an underwater welder is anything but average. These professionals often work in challenging and unpredictable conditions. Their day might begin with extensive safety briefings, equipment checks, and preparation of the welding gear. Wet suits, helmets, and breathing apparatuses are fitted meticulously since even minor faults can be catastrophic underwater.

Next comes the dive itself, where the welder descends to the job site, sometimes hundreds of feet below the surface. Visibility underwater can fluctuate dramatically depending on location, season, and weather conditions. Some days, the water is crystal clear; on others, it might be murky or filled with particles. The welder must adapt quickly, relying on muscle memory, training, and intuition.

Once at the worksite, the diver positions themselves expertly to begin welding seams, attaching new components, or repairing damage. Tasks require intense concentration despite the cold, noise, and water pressure pressing against the body. Communication with surface teams is continuous, adding a vital layer of safety and coordination.

After completing the welding tasks, the diver ascends slowly to avoid decompression sickness, a dangerous medical condition caused by rapid pressure changes. Back on the surface, the equipment is cleaned and inspected, and the welder undergoes health checks before resting and preparing for the next dive.

The Risks That Make Underwater Welding So Dangerous

It’s often said that underwater welding is one of the most dangerous jobs, and that reputation is well deserved. The combination of electricity, water, extreme pressure, and potentially unstable structures creates a perilous environment. Let’s break down the main risks:

| Risk Factor | Description | Potential Consequences |

|---|---|---|

| Electric Shock | Water conducts electricity, and wet welding uses electrical currents. Equipment failure or improper handling can cause shocks. | Severe injury or death from electrocution. |

| Drowning | Equipment malfunction, entrapment, or panic underwater can cause drowning if the diver cannot access air or ascend safely. | Fatality or serious injury. |

| Decompression Sickness (The Bends) | Rapid ascent causes nitrogen bubbles to form in the bloodstream, leading to joint pain, paralysis, or death. | Permanent injury or fatality if untreated. |

| Explosions and Fires | Underwater structures sometimes contain flammable gases or materials. | Severe burns, injury, or death. |

| Physical Trauma | Falling debris, unstable structures, or marine life attacks can cause injury. | Broken bones, lacerations, or fatal injury. |

| Hypothermia | Cold water exposure leads to body heat loss. | Loss of motor function, unconsciousness, death. |

All these dangers require underwater welders to be highly trained and vigilant at all times. Thanks to advancements in technology and safety protocols, the job has become somewhat safer than in the past, but it remains an occupation where risks loom large.

Training and Certification: Preparation for the Deep

Given the inherent dangers of underwater welding, proper training and certification are absolutely critical. The path to becoming an underwater welder requires a blend of commercial diving skills and specialized welding knowledge. Here’s a typical journey for aspiring underwater welders:

- Basic Welding Training: Learn standard welding techniques including Shielded Metal Arc Welding (SMAW) and Gas Tungsten Arc Welding (GTAW).

- Commercial Diving Certification: Gain certification from an accredited diving school that offers complete training in dive physiology, gear management, and safety.

- Underwater Welding Program: Professional underwater welding courses focus on welding in wet and dry environments, underwater safety procedures, and problem-solving.

- On-the-Job Training: Experience is crucial. Apprenticeships and on-site mentoring provide practical skills in real work conditions.

- Advanced Certifications: Divers may seek additional qualifications in specialized fields, such as hazardous environment diving or deep-sea welding.

Successful completion of these steps demonstrates that the welder has not only the technical skills but also the mental resilience to work safely under extreme conditions.

Tools and Technology of Underwater Welding

Underwater welding requires specialized equipment to function effectively and safely. While the basic principle revolves around joining metals, the gear and technology used are uniquely adapted for the underwater environment.

Welding Power Supplies and Electrodes

Underwater welders use waterproof power supplies that regulate and deliver electric current safely despite the surrounding water. The electrodes, or welding rods, are specially designed for underwater applications, often coated with waterproof materials to sustain the arc in wet conditions.

Diving Equipment

The dive suit, helmet, and breathing apparatus protect the welder from cold, provide air supply, and enable communication with surface teams. Many underwater welders wear dry suits that keep them dry and insulated from the cold water.

Support Systems

Surface teams play a crucial role. They monitor the diver’s air supply, welding equipment, and safety status, and manage communications. Some underwater welding projects utilize remotely operated vehicles (ROVs) to inspect welds or prepare surfaces before the diver arrives.

Advanced Technologies

Innovations like hyperbaric welding habitats create dry environments underwater, allowing more precise and safe welding. Additionally, advances in robotics and automation sometimes supplement human welders, although current technology does not yet fully replace divers for complex tasks.

Where Do Underwater Welders Work?

Underwater welders find employment across many sectors that depend on aquatic infrastructure or operations. Some typical workplaces include:

- Oil and Gas Industry: Maintaining and repairing offshore oil rigs, pipelines, and underwater storage tanks are among the most common and lucrative jobs.

- Shipbuilding and Repair Yards: Inspecting and welding ship hulls and underwater components require underwater welding expertise.

- Bridge and Dam Construction: Underwater welders secure key parts of bridges and dams that face constant water pressure and wear.

- Power Generation Facilities: Hydro-electric plants and underwater turbines need maintenance by specialized workers.

- Salvage Operations: Recovering sunken ships or valuable materials sometimes requires underwater cutting and welding.

Each environment presents distinct challenges, from deep sea conditions to murky rivers, but all depend heavily on the skills of underwater welders to sustain critical infrastructure.

How Much Do Underwater Welders Earn?

Given the skills, risks, and hardships involved, underwater welders tend to earn significantly more than surface welders or general commercial divers. Salaries vary widely depending on location, experience, and industry, but the following figures provide a rough idea:

| Position Level | Average Annual Salary (USD) | Remarks |

|---|---|---|

| Entry-Level Underwater Welder | $40,000 – $60,000 | Usually requires certification but limited experience |

| Experienced Underwater Welder | $70,000 – $100,000+ | Several years of experience in oil and gas or marine sectors |

| Specialized/Deep Sea Welder | $100,000 – $150,000+ | Qualified for hazardous or deep water environments |

Keep in mind, pay also typically includes extra benefits such as hazard bonuses, travel allowances, and extensive health and safety coverage due to the high-risk nature of the job.

Famous Incidents and Stories in Underwater Welding

Because of its perilous nature, underwater welding has been the subject of many dramatic and tragic stories, which also highlight the heroism and determination of those who choose this career.

One notable incident occurred during the repair of a critical pipeline offshore where an underwater welder encountered a severe electric shock but managed to survive against all odds thanks to quick action by his diving partner and surface crew. Stories like these underscore the tight teamwork and split-second decisions required in this profession.

Additionally, documentaries and exposés have brought more awareness to how challenging and hazardous underwater welding is, pushing for stronger safety regulations and new technologies to protect workers.

The Future of Underwater Welding: Innovations and Challenges Ahead

Looking forward, the field of underwater welding faces exciting advances along with ongoing challenges. Further innovation promises to enhance safety and efficiency, such as:

- Robotics and Automation: Increasing use of ROVs and autonomous underwater vehicles may reduce the need for human divers in the riskiest tasks.

- Improved Materials: Development of better electrodes and welding materials suited for harsh marine conditions.

- Enhanced Training Methods: Virtual reality simulations allow welders to practice in realistic but safe environments.

- Environmental Considerations: Growth of renewable energy offshore (like wind farms) will require specialized underwater welders who understand these newer technologies.

Despite these advancements, the essence of the job — skillfully fusing metal under water — guarantees that human expertise will remain indispensable for decades to come.

Why Do People Choose This Dangerous Career?

You might wonder why anyone would willingly pursue such a risky and demanding career. The answer lies in a combination of factors:

- Adventure and Challenge: Many underwater welders are drawn by the excitement of working in a unique and extreme environment.

- High Earnings: The lucrative pay often outweighs the risks for professionals and their families.

- Skill and Pride: Mastery of such a complex craft brings high professional satisfaction.

- Career Opportunities: Strong demand for skilled underwater welders offers job stability in certain sectors.

- Love of Diving: Many come from scuba diving or commercial diving backgrounds and enjoy the underwater lifestyle.

While certainly not a career for everyone, for those who thrive on challenge and adventure, underwater welding offers a unique blend of both.

Conclusion: Respecting One of the Most Dangerous Jobs in the World

Underwater welding is a rare blend of artistry, courage, and technical skill. Working deep beneath waves to repair, build, and maintain vital structures, underwater welders face extraordinary dangers daily. From electric shocks and decompression sickness to freezing cold and unpredictable environments, the risks are undeniable.

Yet, this demanding job continues to attract skilled professionals who take pride in their expertise and resilience. Advances in technology and safety practices are helping make underwater welding somewhat safer, but the dangers remain real and significant.

Next time you see a bridge span the water or a massive oil rig operating smoothly in the ocean, remember the courageous underwater welders — the heroes of the depths — who make it all possible. Their work literally holds up the modern world beneath the waves.

If you’ve been captivated by this glimpse into one of the most dangerous jobs and feel inspired, consider further research or even a career in this field — one that combines extraordinary risk with remarkable reward.