Welding is a craft that has been fundamental to the development of human civilization, shaping everything from the tools of our ancestors to the skyscrapers that dominate modern city skylines. This fascinating process, which involves joining metals together, has evolved significantly over thousands of years, developing from simple techniques to highly sophisticated modern methods. In this article, we will journey through the history of welding, exploring the ancient welding techniques, breakthroughs in the industrial era, and the cutting-edge technology that defines modern welding today.

This comprehensive exploration will not only provide a chronological timeline but will also delve into the cultural impacts, technological innovations, and practical applications that welding has had throughout the ages. Whether you’re a professional welder, a student studying metallurgy, or simply curious about how this craft has shaped our world, this article has something for you. So, let’s light the torch and start our voyage through the fascinating history of welding.

Early Beginnings: Welding in Ancient Times

Though welding might sound like a modern craft, its roots reach far back into ancient history. The earliest forms of welding were practiced thousands of years ago, where craftsmen realized they could join metals using heat and pressure. Ancient civilizations such as the Egyptians, Greeks, and Romans all used primitive welding methods to craft tools, weapons, and decorative items.

One of the earliest known examples is forge welding, a process that involves heating two metal pieces until they’re malleable and then hammering them together to form a joint. This method was crucial during the Bronze and Iron Ages, when blacksmiths forged swords, armor, and agricultural tools essential for survival and warfare.

It’s fascinating to consider that while ancient craftsmen had none of the technology we take for granted today, their knowledge of ancient welding techniques was surprisingly sophisticated. They understood the importance of controlling temperature and applying pressure to create strong, durable metal joints without modern equipment.

The Art and Science of Forge Welding

Forge welding is often described as both an art and a science. This method required significant skill because craftsmen had to judge the right moment when metals were hot enough to bond but not so hot as to burn through.

The process started with heating the metal in a forge until it reached a red or orange glow. The blacksmith then placed the pieces together and hammered them repeatedly to blend the metals into a unified whole. Skilled artisans could create seamless, incredibly strong joints that stood the test of time.

Many famous ancient artifacts, including weapons dating back to ancient Mesopotamia and Egypt, show evidence of forge welding. This technique was a cornerstone for metalworking long before today’s electric arc or gas welding processes existed.

Early Riveting and Brazing

Besides forge welding, early metalworkers used other methods to join metals. Riveting, where pieces are fastened together using metal pins or bolts, was frequently employed in ancient shipbuilding and architecture. Brazing, involving molten filler metals that join two base metals without melting them, also has roots in the Bronze Age.

These techniques, while not exactly welding by today’s standards, illustrate the human drive to unify metals and create stronger, more complex structures that define an early form of metal joining.

The Evolution of Welding in the Middle Ages and Renaissance

As civilizations expanded and craftsmanship matured, welding technology progressed, especially in the European Middle Ages and Renaissance periods. These centuries witnessed crucial developments in metalworking that laid the groundwork for modern welding.

Blacksmiths became highly respected artisans, crafting not only weapons but also intricate ironwork such as gates, locks, and architectural features. Around this time, foremen and apprentices began experimenting with oxygen and fuel sources to increase forge temperature and improve metal quality.

Advancements in Forge Welding with Improved Bellows and Hammers

The medieval era brought enhanced forging tools including more powerful bellows to pump air and increase temperatures, allowing metals to reach higher malleability. Hammers, anvils, and tongs also became more advanced, enabling craftsmen to work metals more precisely.

These improvements allowed for better-quality welded joints, longer-lasting tools, and even the fusion of different metals to create stronger alloys. Welding was no longer just about function; it became an artistic endeavor as evidenced by ornate ironwork found in castles and cathedrals across Europe.

Began Use of Early Electric Concepts

While the main revolutionary advancements in welding would not appear until later centuries, the late Renaissance period saw tantalizing steps towards electrical experimentation. Early work with static electricity and magnetism hinted at the possibility of using electricity to heat metals, an idea that would come to fruition in the 19th and 20th centuries.

Industrial Revolution: The Birth of Modern Welding Techniques

The Industrial Revolution was a true turning point for welding history. The massive growth in factories, railroads, bridges, and ships demanded faster, stronger, and more reliable metal-joining methods than traditional forge welding or riveting.

This era was characterized by experiments with heat sources beyond simple coal forges, and the birth of the electric arc. The discovery of electricity’s potential to create heat marked a dramatic shift, leading to the birth of techniques still widely used today.

Electric Arc Welding Emerges

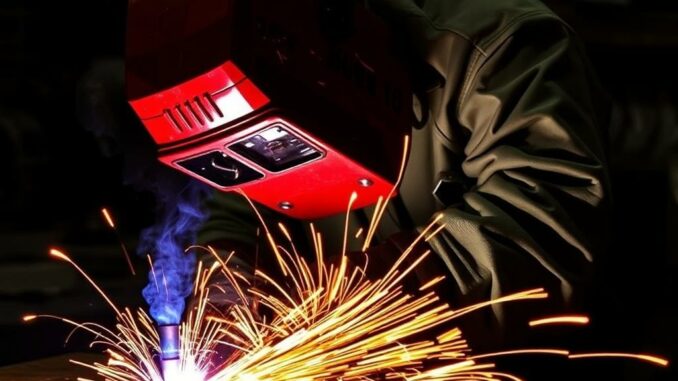

One of the most significant breakthroughs came with the invention of electric arc welding in the late 1800s. This process uses an electric current to create an arc between an electrode and the base metal, melting the metal to form a weld.

In 1881, Auguste de Méritens developed the carbon arc welding method, and in 1890, Nikolay Slavyanov and later Nikolay Benardos perfected it, laying the foundation for welding as an industrial process. The electric arc allowed for faster welding, stronger joints, and opened new possibilities for large-scale manufacturing.

Gas Welding and Brazing

Around the same time, gas welding techniques also emerged, most notably oxy-fuel welding, which uses a flame produced by burning oxygen and a fuel gas (like acetylene) to heat and join metals. Invented by Edmond Fouché and Charles Picard in 1903, this method became popular because of its portability, versatility, and relatively low equipment costs.

Gas welding paved the way for on-site repairs and assembly work that electric arc welding, typically suited for factory settings, could not easily handle. Brazing and soldering techniques also developed concurrently, often used for joining dissimilar metals or delicate components.

Welding in the 20th Century: Refinement and Innovation

As the 20th century progressed, welding technology evolved rapidly to meet the demands of two world wars, rapid industrialization, and the space race. Engineers and metallurgists pushed the boundaries of welding science, improving techniques, equipment, and safety standards.

Shielded Metal Arc Welding (SMAW)

The 1920s and 1930s saw the rise of Shielded Metal Arc Welding (SMAW), also called stick welding, which uses a consumable electrode coated in flux. When the electrode melts, the flux creates a protective gas shield to prevent contamination.

SMAW became a standard for construction, shipbuilding, and heavy equipment manufacturing. Its simplicity and portability meant it could be used in almost any environment, from underwater applications to high-altitude bridges.

Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW)

Post-World War II advancements introduced Gas Metal Arc Welding (GMAW), commonly known as MIG (Metal Inert Gas) welding. This technique uses a continuous wire electrode and an inert gas shield to produce clean, strong welds with increased speed and reduced labor.

Flux-Cored Arc Welding (FCAW), developed later, combined aspects of SMAW and GMAW, allowing welding in outdoor or windy conditions while maintaining a steady weld pool. These hybrid methods transformed welding by offering more flexibility and control for various industrial needs.

Tungsten Inert Gas Welding (TIG)

Tungsten Inert Gas (TIG) welding was developed in the 1930s and gained prominence during and after World War II. TIG uses a non-consumable tungsten electrode and an inert gas shield to produce precise, high-quality welds. TIG is particularly valued for welding thin sheets and exotic metals such as aluminum and stainless steel.

This method requires a higher skill level but is prized in aerospace, automotive, and artistic metal fabrication for its superior control and clean welds.

The Impact of Welding on Industry and Society

Welding has been a cornerstone of industrial development for nearly two centuries and continues to influence how societies build infrastructure, manufacture products, and innovate technology. From the bridges that connect cities to the vehicles we drive and even the spacecraft that explore beyond Earth, welding is everywhere.

Infrastructure and Transportation

The construction of massive infrastructure projects such as railroads, pipelines, oil rigs, and skyscrapers depended heavily on advanced welding methods. Welding has enabled engineers to design complex frameworks and transport systems that are both strong and cost-effective.

| Industrial Application | Welding Technique | Key Benefits |

|---|---|---|

| Shipbuilding | Shielded Metal Arc Welding (SMAW) | Strong joints resistant to fatigue, suitable for large steel plates |

| Aerospace | Tungsten Inert Gas Welding (TIG) | Precision and high-quality welds for light, high-strength alloys |

| Automotive | Gas Metal Arc Welding (GMAW) | Speed and automation-friendly for mass production |

| Construction | Flux-Cored Arc Welding (FCAW) | Welds outdoors efficiently, good penetration for thick materials |

Advances in Welding Tech: Robotics and Automation

By the late 20th century and into the 21st, welding has been further revolutionized by automation and robotics. Robots equipped with sensors and artificial intelligence now perform precise welding tasks faster and more consistently than human welders, greatly improving productivity and safety.

Automated welding has become indispensable in automotive manufacturing lines and heavy industry, where repetitive tasks can now be reliably handled by advanced machines. Not only does this reduce human exposure to dangerous fumes and sparks, but it also lowers costs and speeds up production.

Modern Welding Techniques and Future Trends

Today, welding continues to evolve at a breathtaking pace, adapting to new materials, engineering demands, and environmental concerns. Modern welding technologies encompass laser welding, electron beam welding, friction stir welding, and additive manufacturing welding, each pushing the boundaries of what metals can do.

Laser Welding and Electron Beam Welding

Laser welding uses a tightly focused beam of light to create deep, narrow welds at very high speeds. Its precision and minimal heat input make it ideal for high-tech industries like electronics, medical devices, and aerospace. Similarly, electron beam welding uses a beam of high-velocity electrons in a vacuum to achieve deep penetration welds with minimal distortion.

Friction Stir Welding

Invented in the 1990s, friction stir welding is a solid-state process that joins metals by rubbing them together under pressure, generating heat through friction without melting the materials. This method is especially useful for aluminum alloys in aerospace and automotive industries, offering welds with superior strength and minimal defects.

Additive Manufacturing and Welding

Welding is also central to the burgeoning field of additive manufacturing, commonly known as 3D printing of metals. Techniques like Directed Energy Deposition (DED) rely heavily on welding technologies to build metal parts layer by layer, revolutionizing how components and even entire structures might be constructed in the near future.

Conclusion: Welding’s Timeless Role

The history of welding is a testament to human ingenuity and the endless pursuit of better, stronger, and more efficient ways to join metal. From the glowing forges of ancient blacksmiths through industrial breakthroughs to today’s laser-lit labs, welding remains fundamentally about connection—binding metal and community alike.

As we look forward, welding’s future shines bright with innovations in automation, sustainability, and material science. Whether you’re fascinated by the ancient welding techniques or excited by the potentials of modern methods, it’s clear that welding will continue to be a vital force shaping the tools, technologies, and infrastructures of tomorrow.

- Forge Welding: The earliest and still relevant method from ancient times.

- Electric Arc Welding: Revolutionized industry in the late 19th century.

- Shielded Metal Arc Welding (SMAW): Dominated 20th-century heavy industries.

- Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW): Improved efficiency and outdoor use.

- Tungsten Inert Gas Welding (TIG): High precision for advanced applications.

- Laser, Electron Beam, and Friction Stir Welding: Modern techniques shaping the future.

Thank you for joining this historical journey through the fascinating world of welding. Whether by flame, electricity, or laser, the art of fusing metals will remain a cornerstone of human progress.