When it comes to joining metals, there’s a surprising art to knowing which method to use. Welding often steals the spotlight as the go-to technique, but brazing is a powerful, versatile process that often gets overlooked. Many metalworkers, hobbyists, and engineers might ask: When is brazing the better choice instead of welding? This comprehensive guide will explore the intricate world of brazing, reveal its unique advantages, and help you decide when to choose brazing over welding for your projects.

We’ll dive deep into the art of brazing, its benefits, key differences from welding, and practical applications. Whether you’re a seasoned craftsman or just starting in metalworking, this article will provide valuable insights into one of the most elegant and effective metal joining techniques out there.

What is Brazing?

Brazing is a metal joining process that uses a filler metal with a melting point above 450°C (typically between 450°C and 750°C) but below the melting points of the base metals being joined. The filler metal is heated until molten and flows into the joint by capillary action, bonding the pieces together without melting the base metals themselves. This differs from welding, where the base metals usually melt and fuse together directly.

One of the most fascinating aspects of brazing is its ability to join dissimilar metals with minimal distortion or damage to the base materials. This delicate process requires careful preparation, the right fluxes, precise temperature control, and knowledge of metallurgical properties.

The Brazing Process Step-by-Step

- Cleaning the metals: Before brazing, surfaces must be thoroughly cleaned to remove oxides, oils, and dirt. This ensures proper adhesion of the filler metal.

- Fitting the parts: Close fitting joints with clearances generally between 0.03 to 0.13 mm allow the capillary action to pull the molten filler metal into the joint.

- Applying flux: Flux helps prevent oxidation during heating, allowing the filler metal to properly wet and flow.

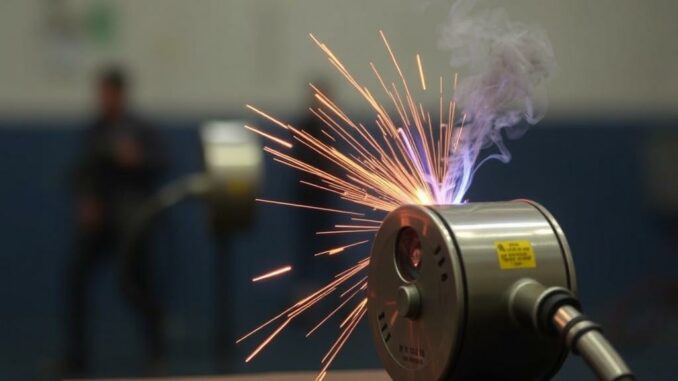

- Heating the assembly: Unlike welding, only the base metals and filler are heated until the filler metal becomes molten—base metals stay solid.

- Filler metal application: The molten filler metal is drawn into the joint by capillary action, creating a strong bond upon cooling and solidification.

Common Filler Metals Used in Brazing

| Filler Metal | Melting Point (°C) | Typical Use | Advantages |

|---|---|---|---|

| Silver-based alloys | 620–780 | High-quality joints, copper, brass, stainless steel | Strong, corrosion resistant, good wetting |

| Aluminum-silicon alloys | 560–590 | Aluminum components | Good wetting, corrosion resistance |

| Phosphorus-based alloys | 600–760 | Copper and copper alloys | Self-fluxing on copper, easy to use |

| Nickel-based alloys | 900–1050 | High-temperature applications | Excellent strength, heat resistance |

What Sets Brazing Apart From Welding?

Many people lump brazing under the same category as welding because they both join metals, but their differences reveal why brazing is its own unique art form.

Key Differences Between Brazing and Welding

- Melting Point: Welding melts the base metals to fuse directly, but brazing melts only the filler metal, leaving the base metals solid.

- Heat Intensity: Welding requires higher temperatures and often specialized equipment, while brazing uses lower temperatures that help preserve the base metals’ properties.

- Joint Strength: Welding typically produces stronger joints suitable for heavy structural use, whereas brazing provides sufficient strength for many applications with less heat damage.

- Material Compatibility: Brazing excels at joining dissimilar metals which can be challenging or impossible with welding.

- Distortion and Warping: Because brazing uses lower temperatures and avoids melting base metals, it results in minimal distortion compared to welding.

To better visualize the differences, consider this side-by-side comparison:

| Aspect | Brazing | Welding |

|---|---|---|

| Temperature | 450–900°C (filler melts) | Typically above 1300°C (base metals melt) |

| Base Metal State | Solid | Molten |

| Materials Joined | Same or different metals | Mostly similar metals |

| Joint Strength | Good | Very high |

| Distortion | Minimal | Can be significant |

| Equipment Needed | Simple torches, furnaces | Arc welders, gas welders |

When to Use Brazing Instead of Welding

Now that we’ve covered the basics and differences, the crucial question arises: When should brazing be chosen over welding? While welding dominates heavy industry, brazing holds a special place in specific scenarios. Let’s explore these contexts.

1. Joining Dissimilar Metals

One of the outstanding advantages of brazing is its ability to join dissimilar metals easily and reliably. For example, joining copper to steel or aluminum to steel can be a challenge with welding due to differences in melting points and metallurgical compatibility. Brazing plays the role of a metal matchmaker, bridging incompatible metals together effectively.

This is especially useful in plumbing, HVAC, electronics, and automotive industries where different metals must be joined without compromising strength or integrity.

2. Minimizing Heat Distortion

Welding’s high heat input can cause warping, dimensional changes, and residual stresses in components. This can be disastrous in precision parts or thin materials prone to bending or cracking. Brazing’s lower temperature means the parts retain their shape, making it ideal for applications requiring exact tolerances and surface finishes.

3. Rapid Assembly and Complex Joints

Brazing can often be performed faster and easier than welding, especially when assembling complex shapes or multiple components simultaneously. It’s often used in mass production processes like furnace brazing of heat exchangers, filters, and electrical components where uniform heating and consistent joints are important.

4. Aesthetic and Clean Joints

Because brazing doesn’t melt the base metal, it generally produces more precise, cleaner joints with less surface oxidation or spatter compared to welding. For artistic metalwork or decorative pieces where appearance matters, brazing can deliver beautiful seams.

5. Repairing Thin or Heat-Sensitive Parts

When repairing delicate or thin parts like jewelry, coins, or thin sheet metal, welding’s heat can cause burn-through or degradation. Brazing provides a gentle alternative that strengthens without risking damage.

Summary: When to Use Brazing

- To join dissimilar metals that welding can’t easily or reliably fuse.

- When controlling distortion and warping is critical.

- For faster, batch production of complex assemblies.

- When clean, aesthetically pleasing joints are desired.

- Repairing or joining heat-sensitive or thin materials.

Common Applications of Brazing

Understanding the ideal scenarios helps, but seeing real-world applications makes the advantages resonate even more clearly. Brazing is everywhere when you know where to look!

1. HVAC and Plumbing

Heat exchangers, air conditioners, and refrigeration systems rely heavily on brazing to join copper tubing and fittings. The strength and leak-proof nature of brazed joints are vital in these systems, where welding is less common due to the sensitive thin tubing.

2. Electrical and Electronics Industry

The electronics industry often uses brazing to assemble components with meticulous connections — connecting dissimilar metals without compromising conductivity or integrity. Brazing also occurs in producing connectors, relays, and sensors.

3. Automotive and Aerospace

Components like radiators, fuel lines, and hydraulic systems benefit from brazing’s ability to provide strong, corrosion-resistant joints without compromising the materials’ heat treatment or properties. Aerospace manufacturers turn to brazing for heat exchangers, fuel systems, and turbines to conserve weight and maximize efficiency.

4. Jewelry Making and Art

Jewelry makers favor brazing for joining precious metals because it offers delicate control and results in elegant joins without melting or damaging the fine metals. Artists use brazing to create intricate, beautiful works that need strong joints without welding’s heavy heat effects.

5. Tooling and Repair Work

Tools damaged by heat or wear can be brazed to build up surfaces or attach parts without extensive heat damage. It’s a go-to process for toolmakers and repair shops worldwide.

The Science Behind a Great Brazed Joint

Brazing might seem straightforward, but the science behind a strong, lasting joint is fascinating and precise. Understanding the metallurgical principles and the factors influencing a joint’s quality will empower you to master the process fully.

Capillary Action

Capillary action is the heart of brazing. When the filler metal melts, it is drawn into the tiny space between closely fitted base metals by surface tension. The size of this gap matters hugely—too wide and capillary action fails; too tight and the filler metal cannot flow.

Metallurgical Bonding

Brazing forms a metallurgical bond between the filler metal and base materials through diffusion and wetting. The filler metal interacts with the base metal surfaces, forming intermetallic layers that create a durable joint. Managing these interactions ensures strength without brittleness.

Flux’s Critical Role

Flux removes oxides and prevents further oxidation during heating, assisting filler metal flow and adhesion. Using the right flux type and applying it correctly are crucial steps often underestimated by beginners.

Factors Affecting Brazed Joint Quality

| Factor | Impact | Considerations |

|---|---|---|

| Joint Clearance | Controls filler flow; affects strength. | Maintain 0.03–0.13 mm for proper capillary action. |

| Heating Method | Uniform heat ensures even flow. | Use torches, furnaces, or induction depending on size. |

| Flux Application | Prevents oxidation, aids wetting. | Apply evenly and in correct amounts. |

| Surface Cleanliness | Contaminants weaken joints. | Clean thoroughly with solvents/grinding. |

| Filler Metal Selection | Affects melting point, corrosion resistance. | Match filler to metals and application requirements. |

Tools and Equipment for Brazing

Setting up for brazing requires specific tools but is often more accessible and affordable compared to welding setups. From simple shop torches to elaborate furnace systems, the choice depends on the project scale and precision.

1. Heat Sources

- Propane or MAPP Gas Torches: Common for small to medium parts, portable and versatile.

- Oxy-Acetylene Torches: Provide higher temperatures, suitable for tougher metals and larger assemblies.

- Induction Heaters: Efficient for precision heating and production environments.

- Furnaces: Used for batch brazing where multiple parts are heated uniformly.

2. Filler Metals and Fluxes

Stocking the right filler metals and fluxes for your chosen metals ensures quality joints. Silver alloys are popular all-rounders, while phosphorus alloys shine with copper. Flux types vary from liquid to paste or powder.

3. Safety Equipment

Brazing involves intense heat and potentially harmful fumes, so appropriate safety gear includes gloves, goggles, ventilation, and fire-resistant clothing. Safety should never be compromised.

Tips for Successful Brazing

Whether you’re a beginner or looking to refine your technique, these practical tips will help you avoid common pitfalls and create strong, beautiful brazed joints every time.

- Prepare and clean surfaces thoroughly. Even slight contamination can weaken a joint.

- Ensure proper joint clearance. Too tight or too loose gaps spoil capillary action.

- Select the appropriate filler metal and flux. Match them to base metals and operating conditions.

- Apply flux evenly and sparingly. Too much flux can cause inclusions and poor flow.

- Heat the assembly evenly. Avoid overheating or underheating parts.

- Allow filler metal to flow naturally by capillary action. Do not force or move parts during cooling.

- Clean the joint after brazing. Remove flux residue to prevent corrosion.

- Practice on scrap pieces first. To develop a feel for the process before working on valuable parts.

Common Myths About Brazing

Despite its effectiveness, brazing is often misunderstood. Let’s debunk a few myths that may be holding you back from trying it:

- “Brazing is weak and not durable.” While brazing typically doesn’t reach weld-level strengths, brazed joints can still exceed the strength of the base metals themselves and provide excellent durability for many applications.

- “Brazing is only for copper.” Brazing is effective on a wide variety of metals, including stainless steel, aluminum, nickel alloys, and more.

- “You have to be a highly skilled welder to braze.” Brazing is often easier to learn and execute than welding, making it accessible even to hobbyists.

- “Brazing is outdated.” Brazing remains critical in modern industry, especially for complex assemblies and high-tech applications.

Conclusion: Embrace the Art of Brazing

Brazing is a fascinating, nuanced, and highly valuable technique in the metal joining world. Knowing when to use brazing instead of welding can save you time, money, and headaches while opening doors to joining materials that welding struggles with. Its ability to work with dissimilar metals, minimize distortion, and produce clean, precise joints gives brazing a permanent place in the toolkit of metalworkers and manufacturers alike.

Whether you’re repairing a delicate piece of jewelry, assembling complex heat exchangers, or exploring new manufacturing methods, embracing the art of brazing will expand your capabilities and craftsmanship. So next time a joining challenge arises, pause—consider brazing before welding. You may find it’s exactly the solution you need.

Happy brazing!