SQLITE NOT INSTALLED

Welcome. If you work with metal, you know the truth: the weld is only as strong as the preparation that goes into it. Schweißnahtvorbereitung — weld seam preparation — is a simple phrase that hides a world of detail. It covers everything from the first scratch of an angle grinder to the final tack weld that holds two plates in place. In this article I’ll walk you through Schleifen (grinding), Entfetten (degreasing/cleaning), and Spannen (clamping/fixturing) in practical, conversational detail. By the time you finish, you’ll have a clear, usable picture of how to get repeatable, high-quality welds every time.

Why Schweißnahtvorbereitung matters

It’s tempting to rush from cutting metal to welding, but Schweißnahtvorbereitung is where success is built. Proper grinding, degreasing, and clamping reduce porosity, improve penetration, prevent cracks, and keep distortion to a minimum. Neglect these steps and you’ll waste time cutting out bad welds, reworking assemblies, and explaining failures.

This article explains the how and why of each step. I’ll include practical tips, material-specific advice, safety notes, lists of recommended tools and consumables, tables comparing methods, and checklists you can use on the shop floor. Whether you’re a hobbyist or a pro, understanding these basics will help you produce stronger, cleaner, and more consistent welds.

Overview: The three pillars — Schleifen, Entfetten, Spannen

Think of Schweißnahtvorbereitung as three pillars that support a good weld: Schleifen (preparing edges and surfaces), Entfetten (removing oils, grease, and contaminants), and Spannen (holding parts in place with proper alignment and minimal stress). They are distinct but tightly linked. Grind too aggressively and you change the metal’s microstructure; clean too little and you trap contaminants; clamp incorrectly and you invite distortion or misalignment.

Throughout this guide I’ll use these German terms often because they’re concise and industry people use them across languages. You’ll also see practical steps and checklists that bring these three pillars together into a reproducible workflow.

Table of contents

- Introduction: why it matters

- Understanding joint types and when preparation matters

- Schleifen — grinding, beveling, and edge prep

- Entfetten — removing contaminants safely and effectively

- Spannen — clamping, fixtures, and tack welding

- Material-specific advice (steel, stainless, aluminum, cast iron)

- Tools, abrasives, chemicals, and consumables

- Quality control: inspection, tests, and standards

- Common problems, troubleshooting, and fixes

- Checklists and sample workflows

- Final thoughts

Understanding joint types and when preparation matters

Before you grind, clean, or clamp, you need to think about the joint. Different joint types require different preparations. The main categories are butt joints, fillet joints, lap joints, edge joints, and tee joints. Each can be single- or double-sided, with or without backing, and with variable groove geometries.

If you’re welding thin sheet metal you might only need a quick edge clean and a narrow root gap. For thick plate, every detail matters: bevel angle, root face, root gap, and surface cleanliness influence penetration, fusion, and the risk of defects. For stainless steels and aluminum, surface contamination and oxides affect weldability more severely than for mild steel. That’s why the Schweißnahtvorbereitung chain of Schleifen, Entfetten, Spannen must be tailored to the joint and the material.

Joint geometry basics

Here’s a simple table comparing common joint types and typical preparation needs. Use this as a rough guide — your project’s WPS (Welding Procedure Specification) or fabrication drawings should be the final authority.

| Joint Type | Typical prep | Critical considerations |

|---|---|---|

| Butt (single V) | Bevel to specified angle, root face, root gap; remove mill scale; degrease | Control gap for penetration; keep bevel angle consistent |

| Double V | Bevel both sides; grind to remove scale; tack to maintain alignment | Reduce welding distortion; fill from both sides if thick plate |

| Fillet (T or corner) | Remove paint and scale near joint; chamfer edges if thick | Ensure good fit-up and avoid excessive root reinforcement |

| Lap | Clean contact surfaces; clamp to avoid gaps; possible edge bevel | Minimize crevice corrosion, particularly on stainless or coated metals |

| Edge | Control edge straightness; remove burrs; possible bevel | Suitable for thin materials only in most cases |

When to be strict (and when it’s okay to be relaxed)

Not every project needs shop-floor perfection. Structural, pressure-vessel, or aerospace welds demand rigorous Schweißnahtvorbereitung and documentation. Cosmetic or low-stress items can tolerate looser standards. However, common sense suggests you never skip basic Entfetten — oil and grease on the weld path is a common root cause of porosity and poor fusion. Similarly, poor Spannen can make even the best welders produce rejects. So be pragmatic: scale the effort to the part’s function but never bypass essential cleaning and secure fixturing.

Schleifen — grinding, beveling, and edge preparation

Schleifen is where the metal gains the correct shape and surface for welding. It includes removing mill scale, grinding bevels for groove welding, smoothing edges for fillets, and sometimes preparing a finish. Proper Schleifen improves weld penetration, reduces inclusions, and helps the welding torch or electrode access the joint reliably.

Tools for Schleifen

You have many tool options. Choose the right one for the job and the metal:

- Angle grinders (with flap discs, grinding wheels, or cutoff wheels)

- Belt grinders for large surfaces and fast stock removal

- Die grinders for tight spaces and delicate work

- Cutting torches or plasma cutters for rough bevels on thick plate (followed by grinding)

- Manual files for fit-up and final adjustments

- Beveling tools or beveling machines for consistent bevel angles on production runs

Abrasives and consumables

Consumable choice matters. Use the correct abrasive type and grit for the task.

- Coated abrasives (silicon carbide or aluminum oxide) for general-purpose grinding

- Zirconia alumina for aggressive grinding and long life on stainless/steel

- Flap discs (composite) for blending and finishing without deep gouges

- Stainless-specific grinding discs that minimize iron contamination when preparing stainless parts

- Non-woven abrasive wheels (Scotch-Brite) for surface cleaning and final finish

Technique: grind smarter, not harder

Grinding is more than brute force. Use these tips to get good results and avoid metal damage:

- Work with the grit: start coarse to remove stock, then progress to finer grits for blending.

- Avoid overheating thin sections — long passes with an angle grinder can heat the metal, changing microstructure and making it brittle. Use intermittent passes and cool with compressed air or water only when appropriate for the material and process.

- On stainless steel, use dedicated discs or non-ferrous finishing tools to avoid embedding iron particles that later cause rust.

- Keep the tool at a consistent angle and pressure to make a predictable bevel.

- For V-grooves, follow specified bevel angles and root face dimensions; use templates or gauges for repeatability.

Bevel shapes and why they matter

Bevel shape influences filler metal volume, heat input, and access. Typical bevels include V, double V, J, U, and bevel with root face. The choice depends on plate thickness, welding process (SMAW, GMAW, GTAW, SAW), and required weld properties.

Example: a thick plate might use a J-groove to reduce filler metal while retaining full penetration. A simple V is common for moderate thickness and ease of preparation. The key is consistency: the welder needs predictable geometry to maintain a stable arc and proper filler distribution.

Common grinding mistakes

Avoid these common errors that sabotage welds:

- Grinding too aggressively on stainless steel with carbon steel wheels — leaves ferrous particles and leads to rust.

- Creating razor edges that are brittle or crack during welding.

- Overheating edges, causing color changes and loss of corrosion resistance in stainless materials.

- Not grinding deep enough to remove scale, coatings, or hard spots from cutting/laser/plasma processes.

- Inconsistent bevel angles across the length of the joint, causing variable penetration and potential defects.

Schleifen checklist

- Confirm joint design and bevel specs from drawings or WPS.

- Select correct tool and abrasive for the material.

- Remove coatings, mill scale, or foreign material to the required depth.

- Produce consistent bevel angle and root face to tolerance.

- Deburr edges and remove sharp cusps that can crack.

- Clean grinding debris before degreasing step.

Entfetten — removing oils, grease, and contaminants

Entfetten is often overlooked but crucial. Oils, drawing compounds, cutting fluids, fingerprints, and residual lubricants from handling create obstacles to proper fusion. During welding, these materials vaporize and can create porosity, inclusions, and slag problems. They can also create localized oxides that interfere with shielding gas effectiveness on processes like TIG and MIG welding.

Types of contaminants and their effects

Common contaminants include:

- Oils and greases: often create porosity and poor wetting.

- Cutting fluids and coolants: may contain emulsified oils that are sticky and hard to remove.

- Paints and coatings: require removal to prevent trapped gases or contamination.

- Oxides and mill scale: can inhibit fusion if not removed.

- Solder fluxes or previous welding residues: can cause poor adhesion and corrosion.

The effect of these contaminants ranges from cosmetic discoloration to catastrophic weld failure. How you remove them depends on the substance and the material.

Cleaning methods

There’s no single best method — the right choice depends on the contaminant and the material. Here are common approaches:

Solvent cleaning

Solvents like isopropyl alcohol (IPA), acetone, and commercial degreasers remove light oils and fingerprints quickly. Use non-chlorinated solvents unless your process or safety rules allow chlorinated versions, and ensure good ventilation.

- Isopropyl alcohol — good for fingerprint-level oils and quick wipe-downs.

- Acetone — fast, evaporates quickly; flammable and harmful in high concentration; use in ventilated areas and avoid hot surfaces.

- Commercial solvents — formulated for heavy contamination; follow manufacturer safety data sheets.

Alkaline cleaning

Water-based alkaline cleaners dissolve and emulsify oils and are common for shop-floor degreasing. They can be used in immersion tanks or sprayed on parts, then rinsed with water. Alkaline cleaners are safer for operators than many solvents but require thorough rinsing and drying to avoid residue or flash rust on carbon steels.

Vapor degreasing

Industrial shops may use vapor degreasing tanks (solvent vapor condensate) for consistent and thorough cleaning. These systems are efficient and suitable for complex geometries but require significant capital and environmental controls.

Mechanical cleaning

Wire brushing, grinding, and blasting remove scale and corrosion along with light contamination. Use stainless steel wire brushes for stainless to avoid embedding iron. Media blasting (sand, aluminum oxide, glass bead) prepares surfaces well but must be followed by degreasing if grease is present.

Ultrasonic cleaning

Ultrasonic baths with an appropriate detergent clean complex parts and blind holes where manual wiping fails. They’re very effective and can remove both soluble and insoluble contaminants. Good for small parts and precision assemblies.

Steam cleaning

Steam and hot water under pressure work well for removing oils and soluble contaminants from larger parts. Ensure parts are dried quickly to prevent flash rust on carbon steels.

Choosing the right method

Consider these factors:

- Type of contaminant — oil, cutting fluid, paint, scale.

- Geometry — can you reach the area with a wipe, or is immersion or ultrasonic needed?

- Material — stainless demands special care to avoid iron contamination and preserve corrosion resistance.

- Scale and production volume — automated options like vapor degreasing or washing lines make sense at scale.

- Safety and environmental regulations — avoid banned solvents and ensure proper disposal of cleaning fluids and rinse water.

Solvent safety and environmental considerations

Many solvents are flammable, toxic, or regulated. Always consult the Safety Data Sheet (SDS). Use proper PPE: nitrile gloves, eye protection, and respirators when indicated. Work in well-ventilated areas and avoid open flames. For environmental stewardship, prefer water-based cleaners where appropriate and arrange proper disposal or recycling of spent solvents.

Entfetten checklist

- Identify contaminant type and select suitable cleaning method.

- Remove loose debris with compressed air or brush before wet cleaning.

- Use solvent or alkaline cleaner, ensuring full coverage of the weld area.

- Rinse if required and dry thoroughly (hot air, clean compressed air).

- Perform a visual check and a simple contact test (wipe with clean cloth; no residue).

- Proceed to Spannen and tack welding without touching cleaned surfaces with bare hands.

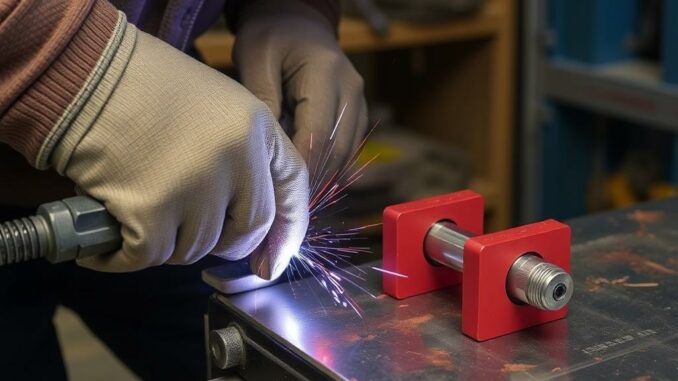

Spannen — clamping, fixtures, and tack welding

Spannen keeps parts where they belong while you weld. Proper clamping eliminates gaps, controls distortion, and ensures alignment. It can mean the difference between a good weld and a sink of rework. Clamping is both art and science: the right fixturing strategy depends on part geometry, material properties, and sequence of welding.

Types of clamps and fixtures

Common clamping tools include:

- C-clamps for general-purpose holding

- Welding magnets for quick positioning (watch for slag adherence and heat effects)

- Screw jacks and toggle clamps for repeatable clamping on fixtures

- Fixture plates and welding tables with T-slots for modular fixturing

- Custom jigs for high-volume production, ensuring repeatability and decreased tack time

- V-blocks, angle plates, and corner clamps for squaring and alignment

Principles of effective clamping

Here are the rules of thumb that lead to dependable fit-up:

- Control distortional forces: apply clamps so that welding shrinkage works against the clamp rather than twisting the assembly.

- Minimize gap variations: use shims or gauge blocks to set root gap to WPS tolerances.

- Use sequential clamping: start at ends and move toward the center, or use opposing clamps to balance forces.

- Consider thermal expansion: heavy clamping that prevents necessary movement during heating can create high residual stresses and cracking.

- Tack in strategic locations: tack welds should be sized and spaced to control fit-up without over-constraining the part.

Tack welding: placement, size, and technique

Tack welds are the temporary stitches that hold the joint. They should be placed and sized to hold geometry under welding heat, not to be final welds. Here’s how to handle tacks effectively:

- Place tacks at regular intervals (e.g., 50–100 mm) depending on joint length and thickness; use the WPS for guidance if available.

- Keep tacks small and consistent so they don’t introduce variable heat input.

- For low-distortion needs, tack opposite sides in sequence (mirror tacks) so forces cancel out.

- Ensure tacks are ground or blended into the final weld if they are in the weld path; otherwise, remove them if they interfere with final weld geometry.

Fixture design for production

For repeated builds, invest in well-designed jigs and fixtures. They speed assembly, reduce errors, and minimize operator variability. Design tips:

- Use modular clamps and adjustable stops for flexibility.

- Include reference surfaces and datum points to ensure consistent alignment.

- Allow access for the welding torch and slag removal.

- Consider thermal management—heavy fixtures can act as heat sinks and increase weld cooling rates; design for controlled cooling where necessary.

Spannen checklist

- Dry-fit and check alignment against drawings.

- Apply clamps to control gap and alignment; use opposing clamps to balance forces.

- Place tacks according to sequence to minimize distortion.

- Verify critical dimensions after tack welding and before final welding.

- Proceed to welding sequence as planned, loosening clamps only when safe.

Material-specific guidance: steel, stainless steel, aluminum, and cast iron

Different metals behave differently during Schleifen, Entfetten, and Spannen. Follow material-specific rules to avoid surprising results.

Carbon and low-alloy steels

These are the most forgiving materials. You can grind with standard abrasives and clean with solvents or alkaline cleaners. However, protect against flash rust after water cleaning and control heat input during welding to avoid hardening in HAZ areas when certain alloying elements are present.

- Schleifen: standard aluminum oxide or zirconia abrasives work well.

- Entfetten: alkaline cleaners or solvents; dry immediately after rinsing.

- Spannen: heavy clamps are fine; watch for distortion due to high shrinkage on large welds.

Stainless steel (austenitic and duplex)

Stainless steel requires the most careful Schweißnahtvorbereitung if you want to preserve corrosion resistance. Don’t contaminate with iron from carbon steel tools; use dedicated stainless wire brushes and grinding discs. After grinding, remove heat tint from weld area if required by application (passivation or pickling may be used).

- Schleifen: use stainless-specific or non-woven abrasives; avoid embedding ferrous particles.

- Entfetten: use solvents like IPA, or water-based cleaners—ensure complete removal of oils. Post-weld pickling or passivation may be needed for critical parts.

- Spannen: use clamps dedicated to stainless if possible; avoid wearing carbon-steel particles into the part.

Aluminum

Aluminum forms an oxide layer nearly instantly after exposure, which affects welding. Grinding and mechanical removal of oxide at the weld path is essential right before welding. Use correct abrasives and be mindful of heat — aluminum dissipates heat quickly so tack welds and filler technique differ from steel.

- Schleifen: use aluminum or non-ferrous abrasives; avoid contamination from steel tools.

- Entfetten: solvents or alkaline cleaners work; ensure the part is dry and oxide-free immediately before welding (wire brush with stainless wire or mechanical sanding).

- Spannen: clamps can leave marks; consider protective pads. Beware of distortion due to differential heating.

Cast iron

Cast iron is brittle and sensitive to thermal shock and stress. Preheat may be necessary, and slow controlled cooling is recommended. Grind away surface graphite and contaminants. Clamping should be gentle; tack welds can introduce stresses that crack the casting.

- Schleifen: remove surface cracks and prepare a clean edge; use coarse abrasives gently.

- Entfetten: remove oils and mold release agents; solvents or hot alkaline cleaning are common.

- Spannen: use minimal clamping pressure and consider preheat and post-weld slow cooling.

Tools, abrasives, chemicals, and consumables: practical list

Here’s a useful consolidated table of tools and consumables for Schweißnahtvorbereitung. It’s designed as a practical shop checklist so you can stock sensibly.

| Category | Items | Notes |

|---|---|---|

| Grinding tools | Angle grinder, belt grinder, die grinder, flap discs, grinding wheels, non-woven wheels | Bring spare discs; use correct RPM-rated discs for your tools |

| Cutting & beveling | Plasma cutter, oxy-fuel torch, beveling machine, cutoff wheels | Follow up rough cuts with grinding for consistent bevels |

| Cleaning chemicals | Isopropyl alcohol, acetone, alkaline cleaners, commercial degreasers, pickling paste (stainless) | Store and use according to SDS; ensure ventilation |

| Cleaning equipment | Ultrasonic tank, parts washer, steam cleaner, pressure washer | Choose based on part size and production volume |

| Brushes & hand tools | Stainless wire brushes, carbon wire brushes, files, deburring tools | Use stainless brushes for stainless parts |

| Clamps & fixturing | C-clamps, welding magnets, toggle clamps, fixture plates, T-slot table | Keep T-slot fixtures organized for repeatability |

| PPE | Respirator, gloves, safety glasses, face shield, ear protection | Essential — grinding and solvents create hazards |

| Inspection | Feeler gauges, welding gauges, straightedge, calipers, magnifier | Measure root gap, bevel angle, and alignment |

Quality control: inspection, tests, and standards

Proper Schweißnahtvorbereitung should be validated, especially in regulated industries. Visual inspection is the minimum. For critical parts, non-destructive testing (NDT) like dye penetrant, ultrasonic testing (UT), and radiography (RT) may be required. Standards such as ISO 5817 (welding quality) and various EN/ASME codes describe acceptance criteria for weld imperfections.

Visual inspection

Before welding, inspect the prepared joint for:

- Consistent bevel angle and root gap

- Absence of visible oils, dirt, or foreign material

- Proper alignment and clamping

- No embedded grinding debris (especially iron on stainless parts)

Pre-weld tests

For critical components, perform tests such as:

- Solvent wipe test — wipe the weld area with a clean cloth and solvent; the cloth should show no visible grease

- Surface contamination test — test kits exist for detecting oil or soluble salts

- Fit-up measurement — use gauges to confirm gaps and angles match WPS

Post-weld NDT options

After welding, you may need NDT depending on the application:

- Dye penetrant (PT) — good for surface-breaking defects

- Magnetic particle (MT) — works on ferromagnetic materials

- Ultrasonic testing (UT) — detects subsurface defects like lack of fusion and longitudinal discontinuities

- Radiography (RT) — reveals internal defects and porosity

Common problems, troubleshooting, and remedies

No matter how careful you are, problems happen. Here are typical issues tied to each pillar and how to fix them.

Schleifen-related problems

- Problem: Overheating and discoloration after grinding. Remedy: Reduce pressure, use cooler passes, use lower RPM or intermittent grinding, and choose the proper abrasive.

- Problem: Embedded iron on stainless. Remedy: Use stainless-specific abrasives, clean thoroughly, and consider pickling/passivation if contamination occurred.

- Problem: Inconsistent bevels. Remedy: Use templates, jig the part, or employ a beveling machine for repeatability.

Entfetten-related problems

- Problem: Residual oil causes porosity. Remedy: Re-clean with a stronger degreaser or alkaline cleaner, and rinse thoroughly; if in doubt, dry and repeat solvent wipe test.

- Problem: Flash rust after water cleaning. Remedy: Use inhibitors, dry rapidly, or follow with a light oil if safe for the process (but remove before welding), or use non-water cleaning methods if rust is an issue.

- Problem: Solvent residues causing weld defects. Remedy: Ensure solvent evaporates fully and use fresh, clean cloths for final wipe.

Spannen-related problems

- Problem: Parts warp during welding. Remedy: Adjust clamping strategy, use backstep welding and balanced sequencing, consider pre-bend or tack placement to counteract expected shrinkage.

- Problem: Clamps get in the way of the weld. Remedy: Reposition clamps or use thin-profile fixtures; use tack welding with temporary supports if necessary.

- Problem: Clamps leave marks on finished surfaces. Remedy: Add protective pads or use softer clamp faces for cosmetic areas.

Sample workflows and checklists for typical scenarios

Below are step-by-step workflows for common shop tasks. Use them as templates and adapt to your WPS and part specifications.

Workflow A — Small steel plate butt joint (shop hobbyist)

- Cut the plates square and to size.

- Clamp pieces on a flat T-slot table and check alignment with a straightedge.

- Grind edges with an angle grinder to remove mill scale and create a slight bevel if plate >3 mm.

- Wipe joint with isopropyl alcohol using lint-free cloths; allow to evaporate.

- Apply C-clamps, set root gap with feeler gauge to ~1.5 mm (or per preference/WPS).

- Place small tack welds every 50–100 mm on alternating sides.

- Re-check alignment and dimensions.

- Perform welding sequence (e.g., root pass, fill passes) keeping bead size consistent.

- Inspect visually and grind any spatter or irregularities as needed.

Workflow B — Stainless steel tube joint (fabrication shop)

- Cut tube ends with precision saw to ensure square faces or specified bevel.

- Use stainless-specific flap discs to remove any oxidation from cutting.

- Clean joint area with acetone or ISO alcohol using clean microfiber towels.

- Clamp using stainless steel clamps or protected surfaces to avoid iron contamination.

- Back purging may be required for full penetration tube welds; prepare purge gas setup.

- Tack weld sparingly; check for distortion and adjust as needed.

- Perform welding with appropriate filler and shielding gas; monitor for heat tint and clean after if required.

- Post-weld passivation may be applied to restore corrosion resistance.

Case studies — practical examples

To illustrate these principles, here are brief real-world case studies showing how proper Schweißnahtvorbereitung saved time and avoided failures.

Case study 1: Porosity nightmare resolved by Entfetten

A small fabrication shop repeatedly saw porosity in MIG welds on a batch of brackets. They tried changing wire and gas but still had issues. A simple solvent wipe test revealed oily residue from a previous machining step. After a time-limited run with proper alkaline cleaning followed by solvent wipe, porosity disappeared. Lesson: sometimes the simplest Entfetten step is the key to consistent welds.

Case study 2: Distortion control through intelligent Spannen

An automotive jig maker struggled with warped frames after welding long seams. The team redesigned fixturing to apply opposing clamps and used a backstep welding sequence that balanced heat input across the frame. Distortion decreased dramatically, reducing grinding and rework time. Lesson: good Spannen and welding sequence planning reduce scrap and improve throughput.

Case study 3: Stainless contamination avoided by proper Schleifen

A food-processing equipment manufacturer had recurring surface rust on stainless assemblies after welding. Investigation showed that staff used carbon steel wire brushes on stainless parts. Switching to stainless wire brushes and non-ferrous abrasives eliminated the contamination and ensured passivation treatments were effective. Lesson: dedicate tools to stainless where possible.

Advanced topics: beveled joint calculations, heat control, and fixture cooling

For advanced practitioners, let’s touch on some deeper topics that balance metallurgy, heat, and fixture design.

Calculating bevel angles and filler volume

Engineers sometimes calculate filler metal volume to estimate weld cost and cooling rate. The cross-sectional area of a V-groove can be approximated and multiplied by joint length to get filler volume. Adjust bevel angle to reduce filler but ensure adequate access for the welding process. Consult WPS guidelines and structural calculations when sizing grooves for critical components.

Heat control and preheat

Certain materials require preheat to prevent cracking (e.g., thick carbon steels with high carbon equivalents). Preheat reduces thermal gradients and slows cooling, reducing the risk of hard microstructures in the HAZ. Follow WPS or material manufacturer guidance for preheat and interpass temperatures. Tools for monitoring include thermocouples and IR thermometers.

Fixture cooling and thermal sinks

Massive fixtures act as heat sinks, speeding weld cooling and changing microstructure. In some cases that helps; in others it harms. Use insulated fixture pads or temporary fixtures if you want to control heat flow. For preassembled production fixtures, consider designing thermal breaks to prevent overcooling.

Regulations, standards, and documentation

For regulated industries you must document Schweißnahtvorbereitung steps: who ground the joint, what cleaning method was used, how parts were clamped, and the tack/welding sequence. Common standards include:

- ISO 5817 — Welding — Quality levels for imperfections

- ISO 3834 — Quality requirements for fusion welding of metallic materials

- ASME Section IX — Welding qualifications (in USA)

- EN standards for pressure equipment and structural steel

Maintain WPS and PQR (Procedure Qualification Record) documents, and record any deviations. Traceability reduces risk in case of failure and supports continuous improvement.

Environmental, health, and safety considerations

The steps of Schleifen, Entfetten, and Spannen expose workers to dust, fumes, solvents, and heavy tools. Prioritize safety:

- Use respiratory protection for grinding and solvent use; dust collectors and local exhaust ventilation are essential.

- Wear impact-resistant eye protection and face shields for grinding sparks and chemical splashes.

- Store solvents in approved containers and handle per SDS guidance (flammable storage cabinets when needed).

- Use gloves and avoid skin contact with caustic cleaners; wash hands after work.

- Keep the work area tidy to prevent tripping hazards that can cause sudden contact with hot parts.

Training and human factors

Good tools and procedures only work when people are trained. Invest in hands-on training and make the right methods easy to follow. Use visual aids — photos of acceptable and unacceptable preparations — and make checklists mandatory for critical builds. Encourage feedback from welders about what works; they are often the best source of practical improvement ideas.

Frequently asked questions (FAQ)

Q: How clean is clean enough before welding?

A: For most carbon steels, a solvent wipe that leaves no visible residue is sufficient. For stainless and aluminum, you must also remove oxides and any embedded iron particles. Follow WPS or industry practice for critical parts, and use a solvent/alkaline/wipe test if uncertain.

Q: Can I grind and weld without degreasing if the parts look clean?

A: Visual cleanliness is not always enough. Oils invisible to the eye can cause porosity. A simple solvent wipe is quick insurance and costs little in time. In production, a consistent cleaning method is worth the effort.

Q: What tack spacing should I use?

A: Typical tack spacing is 50–150 mm depending on part thickness and joint length. For larger weldments, more frequent tacks or stronger tacks are needed to prevent distortion. Always follow WPS if it specifies tack details.

Q: What’s the best abrasive for stainless steel?

A: Use stainless-rated abrasives such as zirconia alumina or non-woven stainless discs and stainless wire brushes. Avoid any tool that has been used on carbon steel without thorough cleaning.

Checklists for shop use — printable and practical

Below are compact checklists you can paste into a shop binder or print for each job. They are distilled from the longer steps above.

Pre-weld preparation checklist

- Confirm joint type and WPS/guidelines.

- Measure and set bevel angle and root gap to specification.

- Grind edges and remove scale/coatings to required depth.

- Degrease/wipe-clean weld area; document method.

- Dry part and perform solvent wipe test.

- Set up clamps, jig, and fixtures; check alignment and dimensions.

- Tack weld according to sequence; re-check fit-up.

- Authorize start of welding.

Welding quality check post-prep

- Visual check for contaminants, inconsistent bevels, or gaps.

- Confirm no hand contact with cleaned surfaces after cleaning.

- Confirm PPE and ventilation in place.

- Record pre-weld measurements and any deviations.

Wrapping up: integrating Schleifen, Entfetten, Spannen into your workflow

Schweißnahtvorbereitung is not an optional luxury — it’s the practical foundation for consistent, strong welds. Schleifen produces the right geometry and surface profile, Entfetten eliminates contaminants that create weld defects, and Spannen holds everything in place so the welding process can work predictably. Taken together, these steps reduce rework, speed production, and protect safety and reliability.

Start small: adopt simple checklists, dedicate tools to stainless or aluminum, enforce solvent wipe tests, and invest in a good T-slot table or set of modular clamps. The benefits compound: fewer porosity issues, fewer failed inspections, and less frustration for welders and fabricators alike.

Further reading and references

If you want to dive deeper, consult the following categories of resources:

- Welding procedure standards (ISO 3834, ASME Section IX, AWS D1.1)

- Material datasheets and manufacturer guidelines

- Chemical supplier SDS and cleaning product guidelines

- Manufacturer manuals for grinders and beveling tools

- Welding handbooks that cover metallurgy and HAZ effects

Final thoughts

Preparation is craftsmanship. Whether you are dealing with a single artful weld on a weekend project or iterating a high-volume production run, Schleifen, Entfetten, and Spannen deserve careful attention. These steps save time, reduce headaches, and make your work stronger and more professional. Invest in good tools, clear procedures, and training. The payoff is welds that look better, perform better, and last longer.

Thanks for reading. If you want, I can create printable checklists, a step-by-step poster for your shop wall, or a tailored workflow based on your materials and welding processes — just tell me what you’re welding and I’ll help you plan the Schweißnahtvorbereitung for success.