SQLITE NOT INSTALLED

If you work with stainless steel—whether in a workshop, a production facility, a kitchen renovation, or a high-precision fabrication job—you already know the single most important goal: keep those welds corrosion-free. In practice, achieving corrosion-resistant welds on stainless steel combines metallurgy, proper welding technique, the right consumables, careful cleanup, and a few well-practiced habits. This article walks you through the topic “Schweißen von Edelstahl: Tipps für korrosionsfreie Nähte” in plain English, step by step, so you come away with trustworthy, practical guidance that actually helps you when you stand in front of the workpiece.

Before we begin, a quick note about keywords: no specific keyword phrases were provided, so I did not intentionally place any special keyword list. Instead, the text focuses on clarity, practical value, and even coverage of the subject so it reads naturally and usefully. Now let’s dive in.

Why stainless steel can be tricky to weld

Stainless steel behaves differently from carbon steel. Its corrosion resistance depends primarily on a thin, stable chromium oxide layer that forms on the surface. When you weld, you disrupt that protective film and change the metal’s microstructure. That means welds must be managed carefully to restore and maintain corrosion resistance.

In addition to oxide-layer disruption, thermal cycles during welding can cause sensitization (chromium carbide precipitation), depletion of alloying elements in the heat-affected zone (HAZ), distortion, and contamination. Each of these can reduce corrosion resistance and, if left unchecked, cause premature failures.

Moreover, stainless steels come in many grades—ferritic, martensitic, austenitic, duplex, and precipitation-hardening types—each with its own weldability characteristics and safeguards. Understanding the basics of these families makes your welding decisions easier and safer.

Core reasons welds corrode

When welds on stainless start to corrode, it’s rarely because of one single cause. Common contributors include contamination (iron-rich deposits from carbon steel tools, weld spatter, rust), improper filler selection, excessive heat input or slow cooling, and inadequate post-weld cleaning or passivation.

Think of welding stainless as an exercise in balance: control your heat, keep contaminants away, choose compatible consumables, and give the welded area the treatment it needs afterward. Do that reliably, and corrosion becomes a minor concern.

Overview of stainless steel grades and weldability

Stainless steels are a broad family. Familiarizing yourself with the common groups will help you choose processes, filler metals, and cooling strategies that protect corrosion resistance.

Austenitic stainless steels (300 and 200 series)

Austenitic grades like 304 and 316 are the most widely used. They have excellent corrosion resistance and are generally the easiest to weld. They are non-magnetic and have high ductility, which helps absorb welding stresses. However, they are sensitive to hot cracking and may suffer from carbide precipitation (sensitization) if cooled slowly in a certain temperature range.

Because of their high chromium and nickel content, austenitic steels typically require matching or slightly higher-alloy filler materials to maintain corrosion resistance in the weld metal and HAZ.

Ferritic stainless steels (400 series)

Ferritic steels (like 430) have lower nickel and higher chromium content than austenitic grades. They are magnetic and generally less ductile. Ferritics can be prone to grain growth and reduced toughness if they’re overheated. They are more sensitive to welding stresses and distortion and can be harder to weld without controlling heat input. Use matching filler materials and reduce interpass temperatures.

Martensitic stainless steels

Martensitic grades (e.g., 410, 420) are heat-treatable and used where strength and wear resistance matter. They are more similar to carbon steels in weld approach but will need post-weld heat treatment (PWHT) to restore toughness and corrosion resistance in many applications. These grades are less commonly used when corrosion resistance is the primary requirement.

Duplex stainless steels

Duplex steels blend austenitic and ferritic microstructures, delivering high strength and excellent resistance to stress corrosion cracking. Welds need particular care to maintain a balanced phase ratio (roughly 50/50). Too much ferrite or too much austenite in the weld or HAZ degrades properties; heat input and filler selection are important to control the balance.

Precipitation-hardening stainless steels

These specialty grades (e.g., 17-4 PH) can provide high strength after heat treatment. Welding may necessitate re-aging or solutioning to regain required mechanical properties and corrosion resistance. Consult alloy datasheets and experienced metallurgists before welding these materials.

Common welding processes for stainless steel

Choosing the right welding process is one of the first decisions that influences weld corrosion resistance. Each process has advantages and limitations depending on material thickness, joint geometry, and the final application.

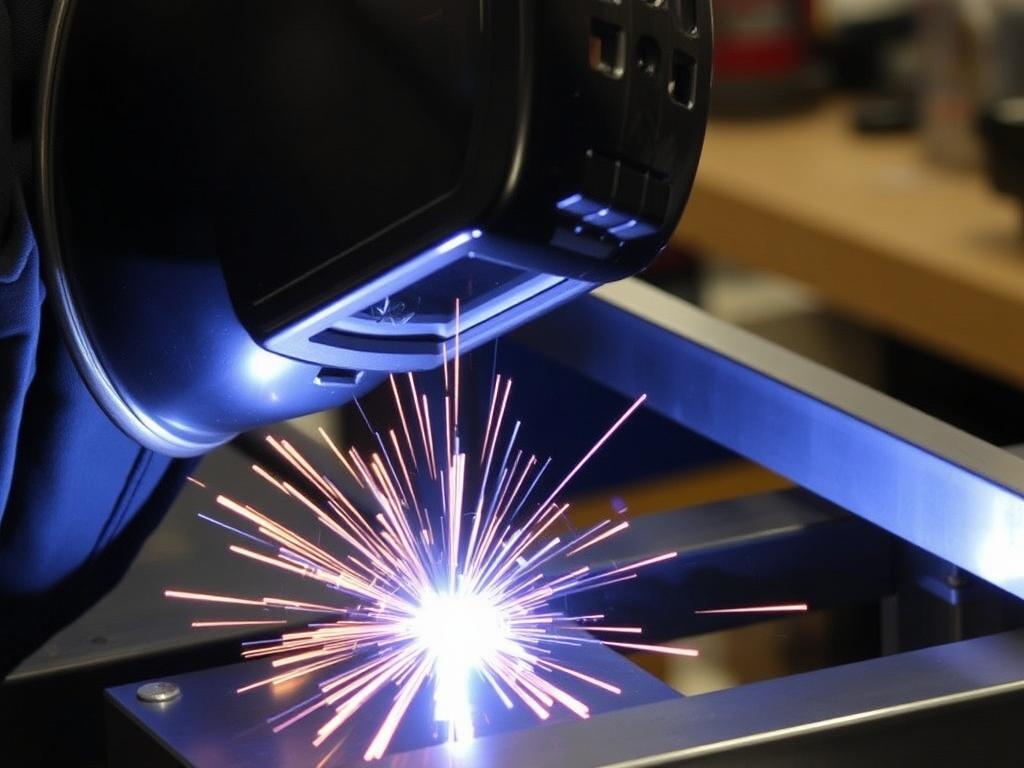

TIG welding (GTAW)

Tungsten Inert Gas (TIG) welding is widely used for stainless because it gives excellent control over heat input and produces clean, high-quality welds. TIG lets you use pure shielding gases and add filler metal only when necessary. For thin materials and critical corrosion-resistant joints, TIG is often the preferred process.

Its drawbacks are slower deposition rates and higher operator skill requirements, but the payoff is a cleaner weld with fewer contaminants and better control of interpass temperatures—key factors in corrosion resistance.

MIG/MAG welding (GMAW)**

GMAW is faster and easier to mechanize than TIG. It works well for thicker sections and production environments. With stainless, use appropriate shielding gases (often argon with a small percentage of CO2 or O2 depending on filler and grade), and choose filler wire that matches or optimizes corrosion resistance. For critical corrosion-sensitive parts, ensure the weld area is kept clean and consider trim-and-passivation steps after welding.

SMAW (stick welding)

Shielded Metal Arc Welding can be used for stainless steels using specially formulated electrodes. It is robust for field repairs, but it can produce slag and spatter and may leave surface deposits that must be removed to restore corrosion resistance. For high-quality corrosion-critical components, SMAW is less common than TIG or GMAW.

Plasma arc welding and laser welding

These high-energy processes create narrow heat-affected zones, minimizing distortion and sensitization. They are used in precision fabrication and when tight control of metallurgy is required. The reduced HAZ is beneficial for corrosion resistance, but equipment costs and setup complexity are higher.

Shielding gases and atmospheres

Shielding gases protect the molten metal from atmospheric contamination. For stainless steel, using the correct gas composition has both metallurgical and surface-finish implications.

Argon and argon blends

Pure argon is common for TIG on stainless steel. For GMAW, argon mixed with small amounts of helium increases heat input and penetration, which can be useful for thicker sections. Adding tiny amounts of oxygen (up to ~2%) or CO2 can stabilize the arc in short-circuit and pulsed GMAW, but be cautious—the reactive gases can slightly oxidize the weld surface and may require more post-weld cleanup.

Back purging and preventing oxide on the root

When welding tubing, pipes, or double-sided joints, protect the inside of the weld zone using inert gas back-purging (commonly argon). Without back purge, the internal surface forms a thick, dark oxide that strongly reduces corrosion resistance and is difficult to remove. For stainless piping that carries corrosive fluids, back-purging is essential for corrosion-free root surfaces.

Shielding techniques for narrow gaps and open roots

Use trailing shields, purge dams, or flow-controlled gas setups to ensure the weld pool and freshly solidified metal remain under a protective atmosphere until they cool enough to form a stable oxide film. Weld turbidity, drafts, and drafts at the workplace can compromise shielding—control the environment when possible.

Choosing appropriate fillers and matching alloys

Filler metals must complement the base material to avoid galvanic differences and to preserve corrosion resistance. Filling with the wrong alloy can create local galvanic cells and weaken resistance to pitting and crevice corrosion.

Match the base alloy when possible

When practical, use a filler that closely matches the base metal’s chemistry—e.g., 308L for 304 base metal, 316L for 316 base metal. Low-carbon versions (the “L” grades) reduce the risk of sensitization because they have less carbon available to form chromium carbides.

Higher-alloy fillers for aggressive environments

In chloride-rich environments or where high pitting resistance is necessary, select higher-alloy fillers such as 312 or 316L+ when joining dissimilar materials, or use a nickel-based filler for joints involving austenitic to ferritic transitions. For duplex steels, choose duplex-matching consumables to maintain phase balance and corrosion resistance.

Table: Common base metals and recommended filler metals

| Base Metal | Typical Filler | Reason / Notes |

|---|---|---|

| 304 | ER308L, 308L | Good match; low-carbon to reduce sensitization |

| 316 | ER316L, 316L | Improved chloride resistance; low-carbon |

| Duplex (e.g., 2205) | ER2209 (duplex), 2209 | Maintains phase balance and corrosion properties |

| 430 (ferritic) | ER430, special ferritic wires | Ferritic filler avoids mismatches and brittle zones |

| Carbon steel to stainless dissimilar | Nickel-based fillers (e.g., ENiCrFe-3) | Prevents galvanic corrosion and brittle intermetallics |

Note: Consult material specifications for exact filler choices—this table provides general guidance, not a complete selection chart.

Joint preparation and fit-up

Good preparation is the low-effort, high-return investment you make before striking the arc. Cleanliness and tight fit-up reduce the amount of welding you must do and the risk of contamination and defects.

Cleaning: remove oils, grease, and surface contamination

Oil, grease, fingerprints, shop dirt, and weld splatter—all of these become focal points for corrosion if they’re left in place. Use solvent cleaning, alkaline cleaners, or degreasers appropriate for stainless steel. Avoid steel wire brushes or tools that transfer iron particles to the surface; if you must use a wire brush, keep it dedicated to stainless only.

Another safe cleaning method is mechanical: Scotch-Brite or non-ferrous abrasives can remove surface oxides and residue without embedding iron as a carbon steel brush would.

Edge preparation and joint geometry

For thin-gauge stainless, often a simple butt joint with a square edge and light gap works best, avoiding excessive bevels that require high heat input. For thicker sections, prepare a groove that allows proper penetration with manageable heat. Minimize root gaps where possible to reduce oxidation on the root side; when the root is exposed, ensure proper back-purging and support.

Clamping and distortion control

Proper fixturing reduces the need for heavy weld passes that introduce more heat. Use clamps and tack welds to maintain alignment. For thin sheets, consider alternating weld sequences or using heat-sink clamps to control distortion. Tack welds should be small and cleaned before final welding to avoid introducing contaminants.

Contamination control: the devil is in the details

Contamination is one of the most frequent causes of poor corrosion performance in stainless welds. Iron contamination is a particular problem because it creates spots that rust visible as brown stains, and these spots can promote localized corrosion in service.

Tools and handling

Use dedicated toolsets for stainless steel: brooms, wire brushes, grinders, and wrenches that are not used on carbon steel. If that’s not possible, thoroughly clean tools before use and remove any iron dust or filings that might transfer to the stainless surface. Even tiny iron particles can cause noticeable surface staining later.

Tack welding and filler wire handling

Keep filler wire spools off the floor and in clean containers. Spools can pick up dust and contaminants that end up in the weld. Also, do not use filler wire taken from a spool that recently sat next to carbon steel welding wire—cross-contamination is more common than you might think.

Heat input, interpass temperature, and thermal control

Heat input controls microstructure in the HAZ. Too much heat can cause sensitization in austenitic steels and phase imbalances in duplex grades. Too little heat may cause lack of fusion or poor wetting by filler metal.

Controlling heat input

Heat input is a function of current, voltage, travel speed, and process efficiency. Use the lowest practical heat input for the joint, keep travel speed steady, and avoid long, slow runs that keep the component in the sensitization temperature range (around 450–850°C for many austenitic steels) for prolonged periods. Pulsed welding modes and smaller electrodes can help reduce heat input while maintaining good penetration.

Interpass temperature

Maintain a controlled interpass temperature—often recommended below 150–250°C for many austenitic stainless steels. For duplex stainless steels, careful control of interpass temperature (often lower than for austenitic) is essential to preserve the balance of ferrite and austenite. Letting parts cool too much between passes can increase the number of passes and overall heat history, but allowing them to stay too hot promotes undesirable microstructural changes. Plan a welding sequence to achieve the intended balance.

Avoiding sensitization and intermetallic phases

Sensitization refers to the formation of chromium carbides at grain boundaries when stainless steel is exposed to certain temperatures, which depletes chromium locally and renders the area susceptible to intergranular corrosion. Intermetallic phases (sigma phase, chi, etc.) can form in high-chromium or high-alloy steels when exposed to extended high temperatures, reducing toughness and corrosion resistance.

Strategies to reduce sensitization

-

Use low-carbon grades (304L, 316L) when welding austenitic stainless steels.

-

Minimize time spent in the 450–850°C sensitization range by controlling heat input and travel speed.

-

Consider stabilized grades (e.g., 321, 347), which contain Ti or Nb to tie up carbon and reduce carbide precipitation in high-temperature service.

These choices are often dictated by the application—food processing and pharmaceutical industries commonly specify low-carbon or stabilized grades for welded assemblies to avoid intergranular corrosion after welding.

Avoiding sigma and other intermetallic phases

Intermetallic formation is more common in duplex and high-alloy stainless steels at intermediate temperatures (roughly 600–950°C). Long exposures in this range or improper filler selection can create brittle phases. Keep heat inputs controlled, use appropriate matching consumables, and avoid prolonged holds at high temperatures during fabrication or repair.

Post-weld cleaning and passivation

Welding removes and disrupts the stainless protective oxide layer. You must restore or enhance the passive layer through cleaning and passivation to regain corrosion resistance. The approach depends on how contaminated or discolored the weld area is.

Mechanical cleaning

Mechanical methods include grinding, brushing with non-ferrous or stainless-only brushes, sanding with non-contaminating abrasives, and bead blasting with inert media. Use opposing strategies for final polishing depending on the desired surface finish: for food-grade or aesthetic surfaces, achieve a uniform finish that avoids crevices.

Pickling and chemical cleaning

Pickling uses acid solutions (usually nitric and hydrofluoric acid mixes) to remove oxides and embedded iron from stainless surfaces. It’s effective but requires proper safety protocols, trained personnel, and waste handling. For small components and critical welds, professional pickling is common.

Electropolishing

Electropolishing is an electrochemical process that smooths and brightens the surface while preferentially removing peaks and embedded contaminants. It produces a very clean, passive surface and is ideal when maximum corrosion resistance and ease of cleaning are needed (e.g., pharmaceutical or food equipment). Electropolishing is more expensive and generally done in a specialized shop.

Passivation with nitric or citric acid

Passivation treatments remove free iron and promote formation of a stable chromium oxide layer. Nitric acid passivation is traditional and effective; citric acid passivation is safer and environmentally friendlier and is increasingly favored where regulations restrict the use of nitric acid. Follow manufacturer instructions or standards such as ASTM A967 for proper passivation procedures.

Surface finishing and polishing

Finishing affects both aesthetics and corrosion behavior. Smooth, consistent finishes reduce crevices and provide fewer sites where corrosive agents can lodge. Polishing also makes sanitary cleaning easier in food and pharmaceutical contexts.

Mechanical polishing approaches

Progressively finer abrasives are used to reach the desired finish. Start with coarse grit to remove weld bevels and defects, then move to finer grits or cloth wheels to eliminate scratches and produce a uniform grain pattern. Always use abrasives dedicated to stainless or new ones that have never touched carbon steel.

Mirror vs. brushed finishes

Brushed finishes hide small scratches and are often used in architectural applications. Mirror finishes are highly reflective and require more careful polishing and often electropolishing. The end-use defines which finish is appropriate from both aesthetic and corrosion perspectives.

Common weld defects and their impact on corrosion

Understanding common defects helps you spot problems early and avoid long-term corrosion headaches. Some defects have immediate effects; others subtly reduce resistance over time.

Pitting and crevice corrosion at welds

Pitting is localized attack that can start in surface imperfections, inclusions, or where chloride ions concentrate. Crevice corrosion occurs in shielded areas like gasket grooves or poor-fitting joins. Both are more likely where the passive layer is damaged or where contamination provides anodic sites. Use proper filler metals, avoid crevices, and ensure clean, tight fit-up to mitigate these risks.

Oxide discoloration (heat tint) and its consequences

Heat tints form when oxygen reacts with heated stainless. Lighter tints are less severe, but dark tints indicate thicker oxides with reduced chromium at the surface. These areas are more susceptible to corrosion. Mechanical or chemical cleaning and passivation remove them and restore corrosion resistance.

Underfill, porosity, and lack of fusion

Porosity traps corrosive media and reduces cross-sectional area, while lack of fusion creates hidden crevices where corrosives collect. Proper technique, correct shielding gas, clean surfaces, and suitable parameters minimize these problems.

Testing, inspection, and verification of corrosion resistance

Inspection gives you confidence that your welds meet both quality and corrosion resistance expectations. Several nondestructive and laboratory methods check for defects and evaluate corrosion performance.

Visual inspection

Visual inspection is the first and often the most informative test. Look for uniform weld bead shape, correct penetration, absence of spatter and undercut, consistent finish, and no signs of heavy heat tint or scale. Lighting and magnification help spot small pitting or inclusions.

Dye penetrant and eddy current testing

Dye penetrant testing is useful for finding surface cracks and discontinuities. Eddy current testing is sensitive to surface and near-surface defects in conductive materials and is used in production settings.

Radiography and ultrasonic testing

Radiographic and ultrasonic tests reveal subsurface defects such as lack of fusion, voids, and inclusions. These are commonly used in pressure vessel, piping, and critical structural applications where corrosion could result in catastrophic failure.

Corrosion testing and lab analyses

For critical components, perform corrosion testing such as pitting potential (ASTM G48), crevice corrosion testing, or salt spray evaluation. Laboratory surface analysis (XPS, AES) can determine contamination levels and chemical composition of surface films. When in doubt, send samples to a corrosion laboratory for analysis.

Practical tips and a welding checklist for corrosion-free seams

This section pulls together practical, actionable tips you can apply. Think of it as the “what to do next” list before you weld, while you weld, and after the arc is off.

Pre-welding checklist

-

Identify stainless grade and check specifications.

-

Choose matching or appropriate filler metal (consider “L” grades for low carbon).

-

Design joints to minimize crevices and ensure easy cleaning.

-

Clean surfaces: degrease and remove any iron contamination.

-

Set up back-purge where needed (tubes, pipes, double-sided welds).

-

Prepare shielding gas selection and verify flow rates.

-

Select appropriate welding process (TIG for thin/critical, GMAW for production thicker parts).

During-welding checklist

-

Use steady travel speed to control heat input.

-

Maintain interpass temperature within recommended limits.

-

Protect root with back-purge and use trailing shields for the outside if needed.

-

Avoid contaminating the weld pool with tools or dirty filler wire.

-

Minimize the number of passes by using efficient welding parameters.

-

Check for and remove weld spatter immediately to prevent embedding.

Post-welding checklist

-

Remove heat tints and dark oxides using appropriate mechanical or chemical cleaning.

-

Passivate the welded area according to ASTM A967 or supplier guidance.

-

Electropolish if the application requires maximum cleanliness and corrosion resistance.

-

Perform visual and, if required, NDT inspections (PT, UT, RT).

-

Document procedures, materials, and any special measures taken to ensure traceability.

Case studies and practical examples

Learning from examples helps translate principles into practice. Here are a few realistic scenarios with recommended approaches.

Example 1: Food-processing pipeline, 316L tubing

Problem: Internal corrosion and sanitation concerns due to welded joints.

Approach: Use TIG welding with ER316L filler, back-purge with argon for root protection, clean weld area with non-metallic brushes, electropolish internally, and perform citric acid passivation. Ensure weld geometry allows easy cleaning and avoid crevices where product residue could collect.

Outcome: Long life, easy sanitation, and no unexpected pitting in service.

Example 2: Architectural handrail, 304 stainless

Problem: Visible rust stains around welds after exposure to urban atmosphere.

Approach: Clean the area thoroughly to remove embedded iron contamination (use pickling paste if necessary), passivate the welds, and ensure all tools are dedicated to stainless to prevent recontamination. Use 308L filler and achieve a uniform brushed finish to mask minor imperfections.

Outcome: Visual uniformity restored and long-term resistance to local staining.

Example 3: Chemical plant heat exchanger, duplex stainless

Problem: Concerns about stress corrosion cracking and phase balance in welds.

Approach: Use duplex matching filler (ER2209), carefully control heat input and interpass temperature, limit interpass temperature to recommended values, and perform post-weld solution annealing if specified by material data. Inspect with UT and do pitting resistance testing on sample coupons.

Outcome: Maintained duplex properties and resistance to chloride-induced stress corrosion cracking.

Safety precautions and environmental considerations

Welding stainless steel involves chemical exposures (fumes contain chromium, nickel, and other elements), acidic pickling chemicals, and electric arc hazards. Protect yourself and the environment by following good safety practices.

Fume control and respiratory protection

Stainless welding fumes may contain hexavalent chromium, especially when welding coated or stainless metals that have been contaminated. Use local exhaust ventilation, fume extractors, and respirators where needed. Ensure respirator selection matches the contaminants and follow workplace safety standards.

Chemical handling and waste

Acids used for pickling and passivation are hazardous. Use appropriate PPE (acid-resistant gloves, face shields, aprons), and follow regulations for disposal. Consider safer alternatives like citric passivation when possible to reduce hazardous waste and improve worker safety.

Electrical and heat hazard control

Follow standard welding safety practices—eye protection with appropriate shade, gloves, flame-retardant clothing, and safety boots. Prevent accidental contact with hot metal, and allow adequate cooling before handling to avoid burns and other injuries.

Advanced considerations for high-performance and specialty applications

Some applications demand exceptionally high corrosion resistance or particular mechanical properties. Specialized alloys, protective coatings, and metallurgical controls become more important here.

Using nickel-based fillers for dissimilar joints

When joining stainless to carbon steel, or when corrosion resistance must be preserved across a transition, nickel-based fillers (e.g., ENiCrFe-3) can act as a corrosion-resistant buffer. These fillers reduce the risk of galvanic corrosion and brittle intermetallic formation that can occur when joining dissimilar metals.

Fabricating for high chloride environments

In marine or chloride-rich chemical environments, select higher-alloy stainless grades (e.g., 316, superaustenitics, duplex) and choose filler metals that increase pitting resistance. Design joints to avoid crevices and specify electropolishing and rigorous passivation where applicable.

Monitoring and corrosion allowance

For critical equipment, incorporate inspection ports, use corrosion coupons or probes, and plan scheduled inspection intervals. In pressure systems, engineering often includes a corrosion allowance to account for gradual material loss over time.

Training, documentation, and process control

Good welding outcomes aren’t accidental—they’re the result of trained operators, documented procedures, and consistent quality control. Establish welder qualifications specific to stainless processes and keep welding procedure specifications (WPS) that include purge requirements, filler types, and interpass limits.

Welding Procedure Specification (WPS)

Create a WPS that documents the process, shielding gas composition and flow, filler metal type, current and voltage ranges, travel speeds, and back-purge requirements. A well-documented WPS helps maintain repeatability and proves compliance when components must meet codes or standards.

Welder qualifications

Qualification records should match the WPS and include sample weld tests that demonstrate both mechanical integrity and corrosion resistance when required. Regular re-qualification keeps skills current and ensures ongoing quality.

Common myths and misconceptions

Let’s clear up some frequent misunderstandings about stainless welding that lead to mistakes:

“Stainless doesn’t rust, so I don’t have to clean it.”

Stainless is more corrosion resistant than carbon steel, but it still corrodes if the passive layer is compromised or if it’s contaminated. Cleaning before and after welding is critical.

“Any filler metal labeled ‘stainless’ will be fine.”

Not all stainless fillers are equal. Selecting fillers that match base metal chemistry, resist expected service conditions (chlorides, temperature), and avoid galvanic mismatches is crucial.

“Passivation is optional.”

For many critical applications, passivation is not optional—it is required to remove embedded iron and restore the protective oxide. Even in less critical uses, passivation extends life and reduces maintenance.

Glossary of key terms

-

Passivation: Chemical treatment that removes free iron and promotes formation of a protective chromium oxide layer.

-

Sensitization: Precipitation of chromium carbides at grain boundaries that reduces local corrosion resistance.

-

Heat-affected zone (HAZ): The region of the base metal whose microstructure is altered by welding heat but which has not melted.

-

Pitting corrosion: Localized form of corrosion that leads to small cavities or “pits” in the surface.

-

Back-purge: Purging the interior of a weld joint with inert gas to prevent oxidation on the root side.

Useful standards and reference documents

Standards help ensure consistent outcomes and are often specified by clients or regulators. Common references include:

-

ASTM A967: Standard for chemical passivation treatments for stainless steel.

-

ASME Section IX: Welding qualifications and procedures for boiler and pressure vessel fabrication.

-

ISO 15614: Welding procedure testing

-

EN standards for fabrication and material grades relevant in Europe.

Always consult applicable standards and material manufacturers’ recommendations for final decisions; they often contain alloy-specific limits and warnings.

Final thoughts: practice, patience, and process

Schweißen von Edelstahl: Tipps für korrosionsfreie Nähte is not a slogan—it’s a practical mission. Welding stainless steel for corrosion resistance is achievable with careful selection of materials and processes, disciplined cleanliness, thermal control, and proper post-weld treatment. The extra attention pays off in longer component life, fewer field failures, and lower maintenance costs.

If you are starting out, focus on mastering one process (TIG is a great starting point for stainless), keep your tools clean and dedicated, and develop a consistent routine for cleaning and passivation. If you are working on critical or complicated assemblies, don’t hesitate to consult metallurgists or experienced fabricators to create WPS documents and testing plans that protect your investment.

Welding stainless is as much art as it is science: the more you understand the “why” behind each step, the more reliably you’ll create corrosion-free, long-lasting welds. Good luck at the bench—keep your argon flowing, your surface clean, and your attention focused, and you’ll get the results you need.

Further reading and resources

To deepen your understanding, search for technical guides from stainless steel associations, manufacturer datasheets for specific alloys and fillers, and welding textbooks that cover metallurgy and process optimization. Practical workshops and certification courses can also accelerate skill development.

Thank you for reading—if you have specific questions about a project, material grade, or welding setup, tell me about the details and I’ll help with tailored advice.