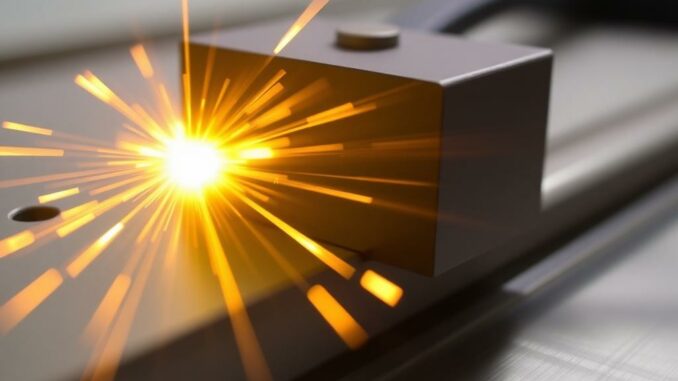

In the ever-evolving world of manufacturing and fabrication, laser welding has emerged as a revolutionary process, transforming the way materials are joined with incredible precision and speed. Whether in automotive industries, aerospace, medical device manufacturing, or electronics, laser welding offers unmatched benefits over traditional welding techniques. This article dives deep into the fascinating world of laser welding, exploring its principles, applications, advantages, equipment, and future trends. By the end, you’ll have a clear understanding of why laser welding is considered the high-tech joining method for precision work.

What is Laser Welding?

Laser welding is a joining process that uses a focused beam of light (laser) to melt and fuse materials together, typically metals or thermoplastics. Unlike traditional welding, which relies on electrical arcs, gas flames, or resistance heating, laser welding harnesses highly concentrated light energy, producing precise, deep, and narrow welds with minimal heat-affected zones.

At its core, the laser generates energy by stimulating atoms to emit photons coherently. This light is then amplified and directed through optics to a small spot on the material surface with extremely high power density. When this beam hits the workpiece, it rapidly heats the area, causing localized melting and fusion upon cooling. Because the laser beam can be controlled with high accuracy, it enables intricate welds, making laser welding ideal for applications requiring tight tolerances and fine detail.

The Physics Behind Laser Welding

Understanding the physics of laser welding helps appreciate why this high-tech process excels in precision work. The key principles include:

- Absorption of laser energy: Different materials absorb laser light differently, which affects the welding process. Metals typically absorb lasers in the infrared or green light spectrum, while some plastics target other wavelengths.

- Heat conduction and keyhole formation: At high power densities, the laser beam not only melts the surface but also creates a vaporized cavity known as a “keyhole.” This keyhole allows deeper penetration as the laser beam follows the cavity, creating deep, narrow welds.

- Rapid cooling: Due to the small heat-affected zone, materials cool quickly, reducing distortion and preserving material properties.

These physics principles make laser welding a game-changer for industries striving for accuracy and repeatability.

Types of Laser Welding Techniques

Laser welding is not a one-size-fits-all process. Depending on the application, materials, and goals, different laser welding techniques are employed. Here are some of the most common types:

1. Conduction Mode Laser Welding

In conduction mode welding, the laser heats the workpiece surface, which melts and welds the materials without forming a keyhole. This mode produces shallow welds with wider beads and is suitable for thin materials or applications where deep penetration isn’t necessary.

2. Keyhole Mode Laser Welding

Keyhole mode is widely used in precision welding. The laser power is high enough to vaporize a small portion of metal, creating a deep keyhole that allows the laser beam to penetrate deeply. This results in narrow, deep welds with excellent mechanical properties. Keyhole mode is preferred for thicker materials and critical, high-strength joints.

3. Hybrid Laser Welding

Hybrid laser welding combines laser welding with another joining method, often arc welding. By complementing laser welding’s precision with arc welding’s gap-bridging capabilities, hybrid welding maximizes productivity and weld quality, especially for challenging or thick materials.

4. Laser Micro Welding

For ultra-fine, small-scale welds—such as in medical devices or electronics—laser micro welding offers exceptional precision. It involves very low laser powers focused on microscopic weld spots, enabling joins with minimal thermal impact.

5. Laser Plastic Welding

Beyond metals, laser welding can also join certain thermoplastics. By using lasers at specific wavelengths absorbed by the materials, plastic components can be bonded with clean, strong seams, useful in automotive interiors and medical instrument assembly.

Advantages of Laser Welding over Traditional Methods

Laser welding has become synonymous with high-tech joining because of distinct advantages it offers over conventional welding processes such as TIG, MIG, and resistance welding. Here are the key benefits that have fueled its widespread adoption:

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Precision and Control | Laser beams can be focused very tightly, allowing welds with minimal width and small heat-affected zones. | Enables joining intricate parts and reduces post-processing work. |

| High Welding Speeds | High power density allows rapid melting and solidification. | Increases throughput and productivity. |

| Minimal Thermal Distortion | Localized heat input prevents warping or damage to heat-sensitive components. | Maintains dimensional accuracy and integrity of parts. |

| Ability to Weld Dissimilar Materials | Laser welding can join materials that are hard to weld traditionally, such as steel to aluminum. | Expands design possibilities and material selection. |

| Automation Compatibility | Laser welding setups integrate easily with robotic arms and CNC systems. | Enhances repeatability and reduces labor costs. |

| Non-contact Process | Laser welding does not require physical contact with the workpiece. | Reduces tool wear and allows welding in hard-to-reach spots. |

Applications of Laser Welding in Industry

The unique qualities of laser welding have made it an indispensable tool in multiple industries where precision, speed, and reliability are paramount. Let’s explore some primary application areas where laser welding truly shines.

Automotive Industry

In automotive manufacturing, lightweight construction and strong joints are critical. Laser welding is used extensively for joining car body components, engine parts, and transmission systems. The ability to perform high-speed, narrow welds allows manufacturers to reduce weight and improve fuel efficiency without sacrificing strength.

- Spot welding of car bodies – Laser welding replaces traditional resistance spot welding, offering stronger and less visible joints.

- Welding of aluminum parts – Laser welding allows joining aluminum in car frames, which is difficult with other methods.

- Battery pack assembly – In electric vehicles, laser welding is used to precisely join battery cells and components.

Aerospace

Aerospace components demand the highest levels of precision and reliability. Laser welding is used for fabricating turbine blades, fuel system components, and sensor housings. The minimal heat-affected zones reduce residual stresses that can affect performance during flight.

Medical Device Manufacturing

The medical industry benefits from laser welding for assembling surgical instruments, implants, and micro-scale devices. The process ensures sterile, contamination-free joints with exceptional precision. Laser welding also facilitates joining of biocompatible materials, critical for patient safety.

Electronics

The miniaturization of electronics demands extremely fine and neat welds. Laser welding is favored for joining tiny components in smartphones, watches, and semiconductors, providing lasting and conductive joints without damaging heat-sensitive parts.

Energy Sector

Laser welding is utilized in the manufacture of batteries, solar panels, and nuclear devices where secure and reliable joints ensure operational safety and performance.

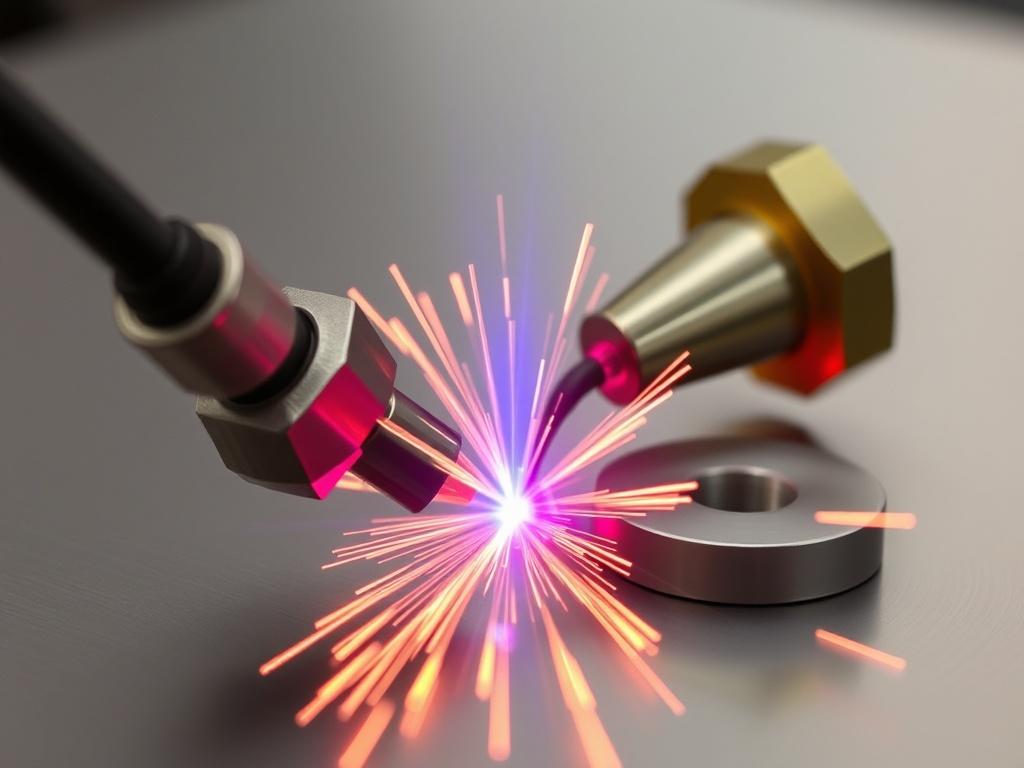

Equipment and Components in Laser Welding Systems

Laser welding setups are sophisticated systems composed of several key components that work in unison to deliver precise energy to the workpiece. Understanding this equipment helps realize the versatility and complexity behind high-tech joining.

Laser Sources

The heart of the system, laser sources generate the coherent beam of light. Types include:

- CO2 Lasers: Emit infrared light at 10.6 micrometers, ideal for cutting and welding metals, but require complex optics.

- Fiber Lasers: Compact and efficient, use optical fibers doped with rare earth elements to produce high-quality beams.

- Nd:YAG Lasers: Solid-state lasers popular in precision welding applications, especially in micro welding.

- Disk Lasers: Similar to fiber lasers but utilize thin disk-shaped gain media, providing excellent beam quality.

Beam Delivery Systems

The laser beam must be transported from the source to the workpiece. Delivery systems include:

- Mirrors and lenses: For CO2 lasers, the beam is directed by a series of mirrors.

- Fiber optics: Fiber lasers use flexible fiber cables to transmit the beam, allowing easy integration with robotic arms.

Focusing Optics

Lenses focus the beam down to a spot size often smaller than a millimeter, controlling the weld width and penetration depth. Adjustable optics enable the operator to change the focus spot for different applications.

Workpiece Positioning Systems

Precision welds require accurate positioning, achieved through:

- Robotic arms: Provide flexibility and repeatability in automated setups.

- CNC tables: Move the workpiece in programmed patterns for complex weld geometries.

Shielding Gas Delivery

Often, an inert gas such as argon or helium is used to shield the weld from atmospheric contamination, ensuring clean and defect-free joins.

Factors Affecting Laser Welding Quality

Achieving flawless welds with laser technology involves controlling several critical parameters. Operators must understand and optimize these factors for the best results.

| Factor | Impact on Weld Quality | Typical Control Method |

|---|---|---|

| Laser Power | Determines depth and width of weld penetration. | Adjust laser output settings. |

| Welding Speed | Too fast can cause incomplete fusion; too slow causes excessive melting. | Fine-tune robot or CNC movement speeds. |

| Focus Spot Size | Smaller spots deliver higher power density; affects weld bead shape. | Adjust focusing optics. |

| Shielding Gas Flow | Prevents oxidation and contamination. | Regulate gas pressure and nozzle position. |

| Fit-up and Joint Preparation | Gaps or misalignment can cause weld defects. | Ensure tight tolerances and clean surfaces. |

| Material Properties | Thermal conductivity and reflectivity affect absorption of laser energy. | Select appropriate laser type and process settings. |

Challenges and Limitations of Laser Welding

Despite its many advantages, laser welding is not without challenges. Some limitations must be considered when selecting it as a joining method:

High Initial Investment

Laser welding equipment requires significant upfront costs, including laser sources, optics, and automation. This can be a barrier for small-scale operations.

Material Reflectivity

Highly reflective materials like copper and gold tend to reflect laser energy, reducing absorption and complicating the welding process. Specialized lasers or surface treatments may be needed.

Joint Fit-up Sensitivity

Laser welding requires precise joint preparation with minimal gaps. Poor fit-up can lead to incomplete welds or defects like porosity.

Health and Safety Considerations

The intense laser beam poses eye and skin hazards. Proper shielding, personal protective equipment, and safety interlocks are mandatory to protect operators.

The Future of Laser Welding: Trends and Innovations

As technology advances, the landscape of laser welding continues to evolve, integrating smart controls and expanding applications. Here are some exciting trends shaping the future:

Integration with Industry 4.0

Smart factory concepts embed laser welding machines with sensors and IoT connectivity. Real-time monitoring and adaptive controls optimize weld quality and efficiency, enabling predictive maintenance and reduced downtime.

Ultrafast and Ultraprecise Lasers

Development of ultrafast laser pulses allows welding without significant thermal damage, opening new possibilities in microelectronics and biomedical devices fabrication.

New Materials and Coatings

Laser welding is adapting to join new composite materials and coated surfaces as manufacturing innovation drives material science.

Miniaturization and Portability

Smaller, fiber-based laser welding machines are becoming more portable, making on-site repairs and fieldwork feasible, especially in aerospace and shipbuilding sectors.

Summary: Why Laser Welding is the High-Tech Joining Solution

Laser welding represents a pinnacle of high-tech joining methods perfectly suited for precision work across diverse industries. Its ability to deliver deep, strong, and clean welds with minimal thermal impact fuels innovation in automotive, aerospace, medical, and electronic manufacturing. While challenges exist, ongoing advancements in laser technology, automation, and materials promise even broader adoption and enhanced capabilities.

For manufacturers seeking superior weld quality, efficiency, and flexibility, laser welding is not just an option—it’s a strategic investment into the future of production excellence.