SQLITE NOT INSTALLED

In the world of manufacturing and metal fabrication, joining techniques are critical to the structural integrity and performance of materials. Among the many methods available, Friction Stir Welding (FSW) stands out as a revolutionary solid-state joining process that has been gaining momentum over the past few decades. Unlike traditional welding techniques that rely on melting metals together, FSW uses friction-generated heat combined with mechanical stirring to fuse materials without reaching their melting point.

In this comprehensive article, we will dive deep into the mechanics, advantages, applications, and future prospects of friction stir welding. Whether you’re an engineer, student, or simply curious about cutting-edge fabrication technology, this article will guide you through the essentials and nuances of this fascinating joining method.

What is Friction Stir Welding?

Friction Stir Welding is a solid-state joining method that joins materials through plastic deformation and heat generated by friction. The term “solid-state” means that the metals are joined below their melting temperature, which distinguishes it from traditional fusion welding.

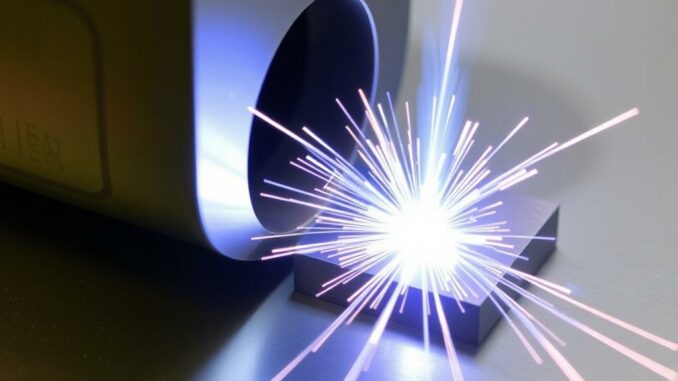

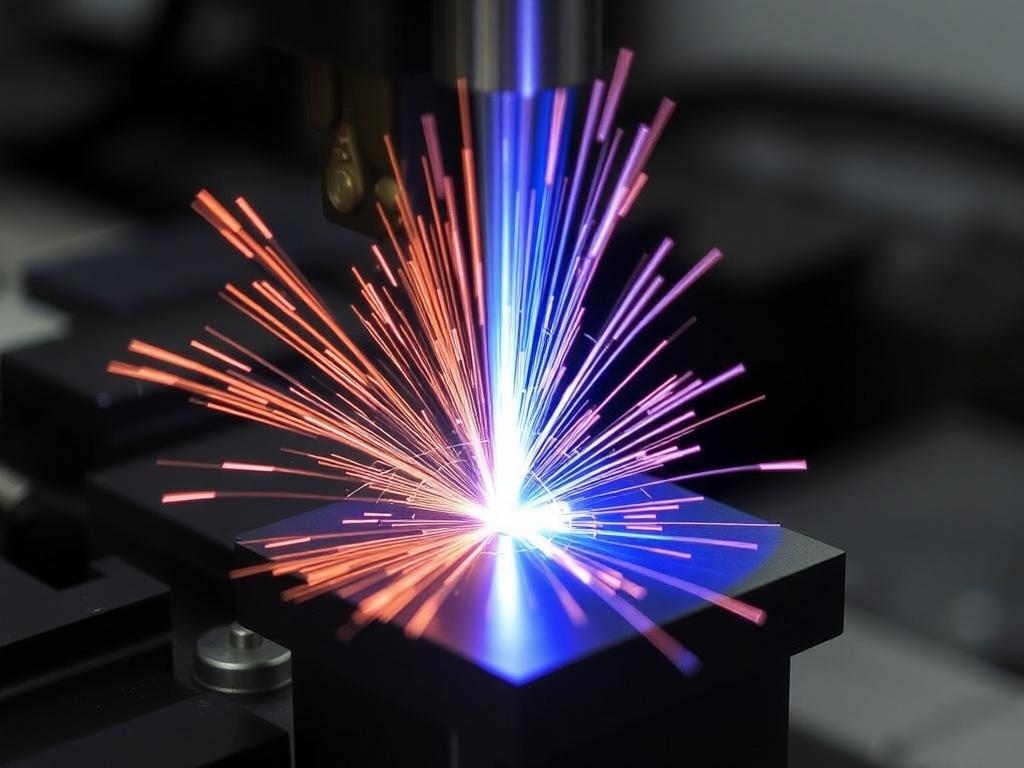

The process involves a specially designed rotating tool with a pin and shoulder. This tool plunges into the joint between two workpieces and moves along the joint line. The friction between the tool and workpieces generates heat, softening the material without melting it. Meanwhile, the rotating pin stirs the softened metals together, creating a strong, defect-free weld.

This mechanism allows joining of different kinds of metals, including aluminum, magnesium, copper, and steel, in ways that were difficult or impossible with conventional welding. The absence of melting reduces many common issues like distortion, shrinkage, and porosity.

The Origins and Development of Friction Stir Welding

Friction Stir Welding was invented in 1991 by Wayne Thomas at The Welding Institute (TWI) in the United Kingdom. Originally developed to solve problems in aluminum alloys used in aerospace and automotive industries, it quickly proved invaluable across numerous sectors.

Since its invention, FSW has evolved rapidly, with innovations such as friction stir spot welding, friction stir processing, and hybrid techniques combining FSW with other joining methods. Today, it is recognized as one of the most promising solid-state welding techniques available.

The Working Principle of Friction Stir Welding

Understanding the working principle of friction stir welding is essential to appreciate its advantages and applications. The process encompasses mechanical and thermal phenomena working together seamlessly.

Key Components of the FSW Tool

- Rotating Pin (Probe): A small cylindrical section that penetrates the joint line, creating friction and stirring the material.

- Shoulder: The larger diameter part that contacts the surface, generating additional frictional heat and containing the plasticized metal.

- Tool Holder: Holds and rotates the tool at precise speeds and applies downward pressure.

Step-by-Step Process Description

- Clamping the Workpieces: The materials to be joined are securely clamped to prevent movement during welding.

- Tool Positioning: The FSW tool is positioned over the joint line, with the rotating pin touching the surface.

- Tool Penetration: The tool plunges into the materials, creating frictional heat and softening the metal underneath.

- Traverse: The tool moves along the joint line at a controlled speed, stirring the plasticized material together.

- Solidification: Once the tool passes, the stirred zone cools and consolidates, forming a strong metallurgical bond.

The combination of frictional heat and mechanical stirring results in good mixing of the material at the interface, producing high-quality welds with fine microstructure.

Materials Suitable for Friction Stir Welding

One of the remarkable features of friction stir welding is its capacity to join a wide range of materials, particularly those difficult to weld by conventional techniques.

Commonly Welded Materials

| Material | Characteristics | Typical Applications |

|---|---|---|

| Aluminum and Aluminum Alloys | Lightweight, good corrosion resistance, challenging to fusion weld | Aerospace structures, automotive frames, shipbuilding |

| Magnesium and Magnesium Alloys | Very light, high specific strength, high reactivity | Automotive parts, aerospace components |

| Copper and Copper Alloys | Excellent electrical and thermal conductivity | Electrical components, heat exchangers |

| Steel and Stainless Steel | High strength, tougher to weld due to melting issues | Structural frameworks, pipelines |

Joining Dissimilar Materials

Another fascinating application of friction stir welding is the ability to join dissimilar metals, which typically have different melting points and thermal expansion rates. Because FSW is a solid-state process, it prevents the formation of brittle intermetallic compounds common in fusion welding.

Examples include aluminum to copper or aluminum to steel joints, which open up new possibilities for lightweight yet strong multi-material structures.

Advantages of Friction Stir Welding

Friction stir welding offers several significant advantages over traditional fusion welding methods. These benefits have made it a preferred choice in many demanding industrial applications.

Key Advantages

- Superior Mechanical Properties: The solid-state process produces fine, equiaxed grains, improving strength and fatigue resistance.

- No Need for Filler Materials: FSW relies on plastic deformation, eliminating the need for consumable electrodes or fillers.

- Minimal Distortion and Residual Stresses: Lower temperatures reduce warping and thermal stresses in the welded parts.

- Environmentally Friendly: FSW does not produce fumes, spatter, or radiation, making it safer and cleaner.

- Energy Efficient: Requires relatively low energy compared to fusion welding.

- Capability to Join Difficult Materials: Metals like aluminum alloys that are prone to defects in fusion welding can be reliably joined.

- Excellent Weld Appearance: FSW creates smooth, uniform joints with minimal surface defects.

Limitations and Challenges of Friction Stir Welding

Like any technology, friction stir welding has its limitations and challenges, especially in initial adoption and specific applications.

Material and Thickness Constraints

FSW is highly effective with softer metals like aluminum but requires specially designed, wear-resistant tools to weld harder materials like steels. Tool material development is an ongoing research area.

Additionally, thickness limitations exist. While FSW can weld sheets as thin as 0.5 mm and plates several centimeters thick, the tooling geometry and process parameters need careful optimization for different thicknesses.

Equipment and Setup Complexity

Friction stir welding demands precision equipment capable of applying accurate downward force, tool rotation, and traverse speed. Initial investment can be higher than traditional welding systems.

Moreover, extensive training and expertise are necessary to optimize welding parameters and tool designs to achieve defect-free welds.

Accessibility and Joint Design

FSW requires the tool to physically access the joint line from one side. This restricts its use to situations where the back side is accessible and the joint is relatively flat.

Complex geometries or closed joints can be challenging to weld with friction stir technology, although robotics and tool variation are helping overcome these issues.

Applications of Friction Stir Welding

The ability of friction stir welding to produce high-quality, reliable welds has led to its adoption in numerous industries. Its solid-state nature makes it particularly valuable in sectors where material integrity is paramount.

Aerospace Industry

In aerospace, weight savings and material performance are critical. FSW is used extensively for joining aluminum alloys in aircraft fuselage and wing panels. Its ability to create strong, lightweight joints without compromising fatigue resistance directly supports aircraft efficiency and safety.

Automotive Sector

Automotive manufacturers use friction stir welding to join aluminum body panels, chassis components, and battery housings for electric vehicles. FSW contributes to weight reduction, improved crashworthiness, and efficient production.

Marine and Shipbuilding

Large aluminum hulls and superstructures of modern vessels are joined using friction stir welding, enhancing corrosion resistance and structural strength. Its minimal distortion helps maintain design tolerances on large panels.

Electronics and Electrical Industry

Friction stir welding is employed in joining copper and copper alloys for electrical connectors, heat sinks, and power generation components, where excellent electrical conductivity is essential.

Railways and Infrastructure

The railway industry benefits from FSW’s ability to join long aluminum extrusions used in train carriages and infrastructure components, delivering lightweight and durable assemblies.

Friction Stir Welding Process Parameters

The quality and properties of friction stir welds depend heavily on the control of process parameters. Understanding and optimizing these is critical in achieving consistent results.

Crucial Process Parameters

| Parameter | Description | Effect on Weld Quality |

|---|---|---|

| Tool Rotation Speed (rpm) | How fast the tool rotates | Affects heat generation and stirring action |

| Travel Speed (mm/min) | Speed of the tool moving along the joint | Influences heat input and weld penetration |

| Plunge Depth | Depth of tool penetration | Ensures sufficient mixing and bond formation |

| Downward Force / Tool Pressure | Force exerted on the workpiece by the tool | Controls bond integrity and weld surface finish |

Parameter Optimization

Finding the right balance between these parameters is a subtle art. For example, too high rotation speed can lead to overheating and defects, while too low travel speed might increase cycle times unnecessarily. Advanced computer simulations and experimental trials help engineers establish optimal conditions for each material and application.

Types and Variations of Friction Stir Welding

Since its introduction, friction stir welding has evolved into various forms tailored for different applications and materials.

Friction Stir Spot Welding (FSSW)

FSSW is a variation where the tool plunges and retracts at a fixed position, creating spot welds instead of continuous seams. This method is increasingly used in automotive manufacturing to replace traditional resistance spot welding.

Friction Stir Processing (FSP)

FSP uses the same principle but focuses on modifying the microstructure and surface properties of metals rather than joining. It can be used for grain refinement, composite material synthesis, and surface hardening.

Hybrid Friction Stir Welding

Some advanced processes combine friction stir welding with other techniques such as laser or arc welding, offering enhanced control, higher welding speeds, and the ability to weld challenging materials.

Future Trends and Innovations in Friction Stir Welding

The future of friction stir welding is really exciting, with ongoing research pushing the boundaries of what this solid-state joining method can achieve.

Tool Material Innovation

Developing new tool materials that can withstand higher temperatures and wear will enable FSW of tougher alloys like titanium and high-strength steels, opening new applications in aerospace and defense.

Automation and Robotics

Integrating robotics and advanced sensors allows real-time monitoring and adaptive control of the welding process, ensuring unparalleled quality and consistency.

New Joint Designs and Geometries

Innovations in tooling and process design will enable friction stir welding of complex shapes, tubular structures, and multi-material joints, further extending its versatility.

Environmental Sustainability

FSW’s energy efficiency and minimal emissions position it as a green technology, aligning with industrial goals to reduce environmental impact.

Summary and Final Thoughts

Friction stir welding represents a paradigm shift in metal joining technology. Its unique solid-state joining method overcomes many limitations of traditional welding by creating high-strength, defect-free joints without melting the base metals. From aerospace to automotive, electronics to shipbuilding, FSW is making manufacturing more efficient, reliable, and environmentally friendly.

While challenges like tooling material limitations and complex joint accessibility remain, ongoing innovations continue to unlock new possibilities. As industries embrace lightweight materials and multi-material designs, friction stir welding is poised to become an increasingly vital technology shaping the future of manufacturing.

Whether you are a technologist, engineer, or enthusiast, understanding the fundamental principles and immense potential of friction stir welding offers insight into how modern materials are joined with precision and excellence today and will be in the future.

If you wish to explore further information or implementation strategies, remember that every successful FSW application starts with mastering the delicate balance of process parameters, materials science, and tool design—a fascinating interplay that makes friction stir welding one of the most innovative and exciting developments in metal fabrication.