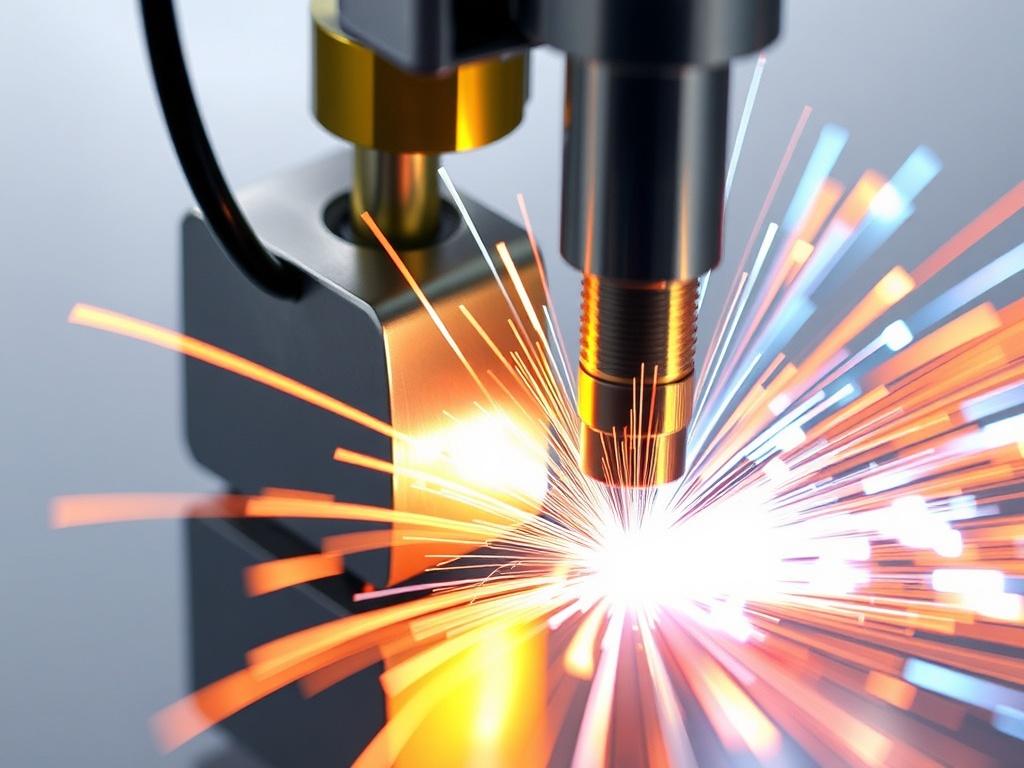

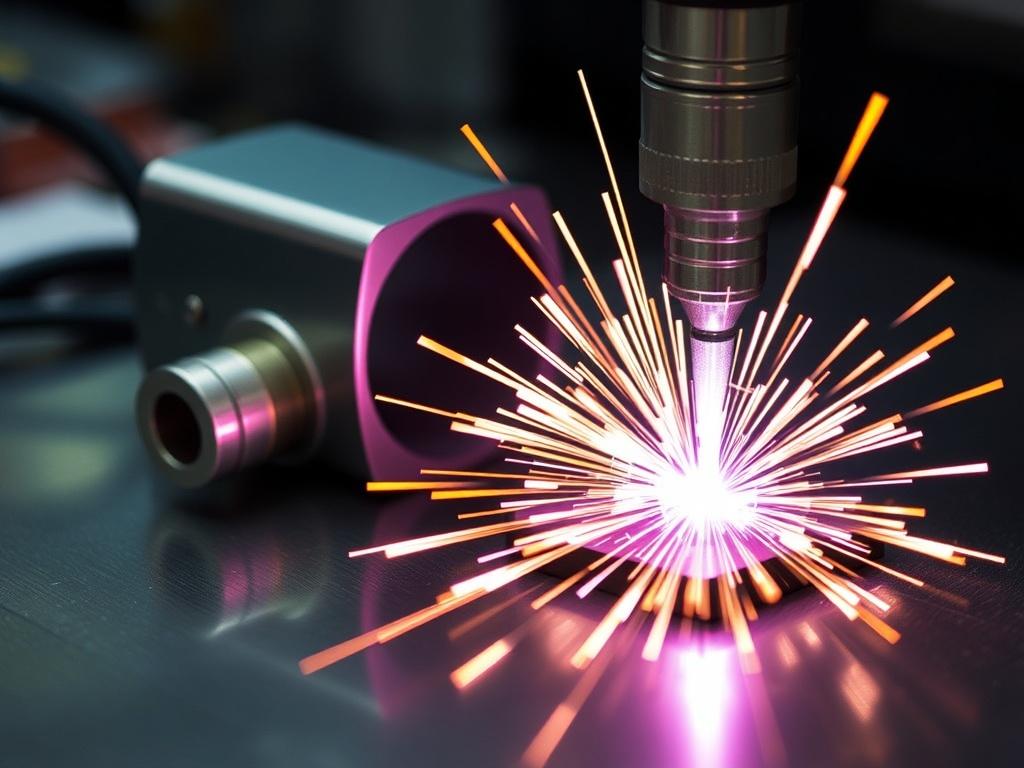

In the world of manufacturing and industrial fabrication, welding techniques have evolved dramatically to meet the ever-growing demands for accuracy, strength, and efficiency. Among these cutting-edge methods, electron beam welding stands out as a revolutionary technology. It offers unparalleled precision and control, opening new horizons for industries such as aerospace, automotive, medical devices, and more. But what exactly is electron beam welding, how does it work, and why is it considered the future of high-precision joining? This article will take you on an in-depth journey through this fascinating welding technique, exploring its principles, applications, advantages, and challenges.

Understanding Electron Beam Welding

Electron beam welding, often abbreviated as EBW, is a fusion welding process that uses a high-velocity beam of electrons to join materials together. When these electrons strike the materials, their kinetic energy is transformed into heat. This intense heat melts the materials at the joint, allowing them to fuse as they cool down and solidify.

Unlike traditional welding methods, EBW operates in a vacuum environment. This vacuum requirement is crucial because it prevents the electron beam from scattering due to collisions with air molecules, ensuring the beam remains focused and intense. The vacuum also reduces oxidation and contamination, leading to cleaner and stronger welds.

The Science Behind Electron Beam Welding

At the core of electron beam welding lies the generation and control of the electron beam itself. The electrons are emitted from a heated tungsten filament cathode and accelerated through a high-voltage electric field. This acceleration boosts their speed to about 30-70% of the speed of light, concentrating an immense amount of energy into a tiny spot. The beam can be precisely maneuvered across the material’s surface using electromagnetic lenses and deflection coils, allowing for controlled and intricate weld patterns.

The high power density achieved by the electron beam means the heat input is very localized. This results in deep penetration welds with minimal distortion of surrounding material, which is especially critical when working with thin or delicate components.

How Electron Beam Welding Works

To truly appreciate the power of electron beam welding, it’s important to understand the step-by-step process:

- Preparation: The materials to be welded are cleaned meticulously to remove any dirt, oils, or oxides that could interfere with weld quality. They are then placed inside the vacuum chamber and securely clamped or fixtured.

- Vacuum Generation: The chamber is sealed and evacuated using vacuum pumps until a high vacuum is achieved, usually below 10^-4 Torr. This low-pressure environment is essential for beam stability and preventing contamination.

- Electron Emission and Acceleration: The cathode (tungsten filament) is heated to release electrons. A high voltage accelerates these electrons, creating a concentrated beam directed at the joint.

- Beam Focusing and Deflection: Electromagnetic coils focus and steer the beam to the desired weld location with extreme precision.

- Welding: The beam energy melts the material at the joint, creating a molten pool. Because of the beam’s intensity, welding occurs rapidly, reducing heat-affected zones.

- Cooling and Solidification: Once the beam moves away, the molten metal cools and solidifies, forming a strong, high-integrity weld.

- Post-Weld Actions: The vacuum is vented, and the welded piece is removed for inspection and any necessary finishing operations.

Visualizing the Process

| Stage | Description | Result |

|---|---|---|

| Preparation | Cleaning and fixturing materials inside vacuum chamber | Materials ready for contamination-free welding |

| Vacuum Creation | Evacuating air to create a high vacuum environment | Stable electron beam with minimal scattering |

| Electron Emission & Acceleration | Generating accelerated electron beam directed at joint | High-energy beam focused on weld area |

| Beam Focusing & Deflection | Using electromagnetics to steer and focus beam | Precise control of weld location & shape |

| Welding | Melting materials at joint via focused beam heat | Strong, deep penetration weld formed |

| Cooling & Solidification | Molten metal cools to form solid joint | High-integrity weld with minimal distortion |

Why Electron Beam Welding is the Future of High-Precision Joining

The unique features of electron beam welding make it an ideal choice for applications demanding precision, strength, and cleanliness. Here’s what sets EBW apart from traditional welding processes and why it’s gaining traction in modern manufacturing:

1. Exceptional Precision and Control

Because the electron beam can be focused into a diameter as small as 0.1 mm, welds can be made with remarkable accuracy. This allows for complex geometries and thin material joining without excessive heat damage or distortion. Industries that rely on miniaturization and fine details, like electronics or medical devices, find EBW indispensable.

2. Deep Penetration with Minimal Heat Input

The high energy density allows electron beam welding to create deep welds quickly. Unlike techniques like TIG or MIG welding which often require multiple passes, EBW can weld thick sections in a single pass. This saves time and reduces the risk of defects.

3. Cleaner Welds Due to Vacuum Environment

Because electron beam welding takes place in a vacuum, oxidation and contamination risks are virtually eliminated. The resulting welds are purer and more consistent, which is critical in aerospace and medical applications where failures are not an option.

4. Versatile Material Compatibility

EBW can be used on a broad range of metals and alloys, including titanium, stainless steel, nickel alloys, and exotic materials. It supports welding dissimilar metals as well, which can be challenging with traditional methods.

5. Automation-Friendly and Cost-Effective in the Long Run

Since the process is highly controlled and repeatable, it integrates well with CNC systems and robotic automation. Although the initial investment in EBW equipment can be significant, the reduction in scrap, rework, and cycle times makes it cost-effective over the life of production.

Applications of Electron Beam Welding

The exceptional characteristics of EBW have enabled its adoption across a diverse range of industries where quality and precision are paramount.

Aerospace Industry

Aerospace components often face extreme conditions and require joints that are both lightweight and incredibly strong. Electron beam welding is extensively used to join turbine blades, jet engine parts, spacecraft assemblies, and more. It ensures minimal distortion and maximum joint integrity—key for flight safety and performance.

Automotive Industry

The push towards electric vehicles and advanced automotive technologies has created demand for welding processes that produce high-integrity joints with low heat impact. EBW is deployed for battery pack assembly, gearbox manufacturing, and parts joining where traditional methods cannot achieve the same precision.

Medical Device Manufacturing

Medical devices like implants, surgical tools, and microelectronic components benefit from the contamination-free environment of EBW. The ability to weld dissimilar metals, such as titanium to stainless steel, is critical for customized implants and devices.

Electronics and Microfabrication

With miniaturization being a hallmark of modern electronics, tightly controlled welding of tiny components is essential. EBW allows for hermetic sealing, precise joining of small parts, and reduced heat damage, preserving component functionality.

Other Industries

- Energy Sector: Welding of heat exchangers, nuclear fuel elements, and other critical infrastructure

- Tool and Die Making: Joining complex tool components with precise control

- Defense: Fabrication of missile and military hardware requiring stringent weld quality

The Advantages and Limitations: A Balanced View

While electron beam welding offers extraordinary benefits, it also comes with challenges that need to be considered for successful adoption.

Advantages

| Advantage | Description | Impact |

|---|---|---|

| High Precision | Focuses energy on a very small area | Enables micro-welding and minimal heat distortion |

| Deep Penetration | Laser-like weld depths in a single pass | Reduces welding time and improves efficiency |

| Vacuum Environment | Eliminates oxidation and contamination | Results in clean, high-quality welds |

| Welds Dissimilar Metals | Joins metals otherwise incompatible by other welding methods | Expands design possibilities |

| Automation Compatible | Easily integrated with CNC and robotics | Increases repeatability and reduces labor costs |

Limitations

- High Initial Cost: Electron beam welding equipment and vacuum chambers require significant capital investment, making it less accessible for small-scale manufacturers.

- Vacuum Requirement: The need to operate in a vacuum limits the size and geometry of parts that can be welded and requires time to evacuate chambers between welds.

- Material Thickness Limitations: While EBW can weld thick materials, very large parts may be difficult to accommodate in vacuum chambers.

- Complex Setup: Requires trained operators and meticulous setup for optimum results.

Electron Beam Welding versus Other High-Precision Welding Techniques

To better understand where electron beam welding fits in the welding landscape, let us compare it with other prevalent high-precision joining technologies.

| Welding Method | Precision | Penetration | Operating Environment | Typical Applications |

|---|---|---|---|---|

| Electron Beam Welding (EBW) | Very High (focused beam) | Deep (single pass thick welds) | Vacuum chamber (clean environment) | Aerospace, medical devices, electronics |

| Laser Beam Welding (LBW) | High (depends on laser focus) | Medium to Deep | Shielding gas or open atmosphere | Automotive, electronics, precision instruments |

| Tungsten Inert Gas Welding (TIG) | Medium to High | Shallow to Medium | Open air with inert gas shield | General fabrication, thin metals |

| Metal Inert Gas Welding (MIG) | Medium | Medium | Open air with shielding gas | Automotive, construction |

Future Trends and Innovations in Electron Beam Welding

As technology advances, electron beam welding is also undergoing transformations to enhance its capabilities and overcome current limitations. Here are the emerging trends shaping its future:

1. Hybrid Welding Systems

Combining electron beam welding with other processes like laser welding or friction stir welding is creating hybrid systems that leverage the strengths of each method. These hybrid systems offer improved speed, flexibility, and quality for complex manufacturing challenges.

2. Larger Vacuum Chambers and Portable Systems

Efforts to design larger vacuum chambers and more portable EBW units aim at allowing bigger or more complex parts to be welded, increasing applicability across new industries and production scenarios.

3. Automation and Smart Monitoring

Integrating advanced sensors, artificial intelligence, and real-time monitoring makes EBW processes smarter and self-correcting. This allows for higher quality assurance and reduced operator intervention.

4. Materials Science Innovations

New alloys and coatings developed in tandem with EBW open possibilities for joining previously difficult materials, enabling breakthroughs in aerospace, energy, and biomedical sectors.

Conclusion: Embracing Electron Beam Welding for the Precision Era

Electron beam welding stands at the forefront of welding technology, offering unmatched precision, speed, and quality. For industries striving to push the boundaries of design and performance, EBW provides a reliable and innovative solution. While it carries some challenges, ongoing advancements and growing adoption worldwide are poised to make electron beam welding an indispensable tool for the future of high-precision joining.

Whether you are a manufacturer, engineer, or simply someone fascinated by the art and science of joining metals, electron beam welding represents a technological leap worth keeping an eye on. It is not just a welding method; it is a bridge to the next generation of manufacturing excellence.